When a pump or pump system fails, it can be frustrating and disruptive. That’s why when choosing a pump, one of the most important things to consider is the component material used in the pump. What the pump is made of will directly impact how it handles certain process media, flow rates and overall reliability.

Comparing Pump Part Materials

The most common types of pump component materials include cast irons, bronzes and low-carbon steels. These are the least expensive to purchase and they are easiest to replace as the parts are readily available. However, they typically will not be as reliable or durable over time. In the end, lower-quality materials can end up costing you more because of continued maintenance, parts replacements, repairs and operational downtime.

Higher-grade materials such as cast steel, nickel aluminum bronze, carbon steel and 300/400-series stainless steel will cost more upfront and replacement parts will also be more expensive to track down. However, these components are usually built to last and the durability and reliability may save you time and money over the long run.

Key Factors to Consider

There are other factors that will determine the types of pump component materials you’ll want to use for specific applications:

- Corrosion — The degradation of metal by chemical or electrochemical reaction.

- Abrasive Wear – The mechanical removal of metal from cutting or abrading actions of any solids carried in the process liquid.

- Cavitation Erosion – The removal of metal as a result of high, localized stresses created by the collapse of cavitation vapor bubbles. This is a common issue with high-suction energy pumps.

Different component materials will react uniquely based on these factors, along with consideration for the desired flow rate and process media. For the most part, however, it comes down to paying more now versus paying more later. You can buy a cheaper pump made with lesser materials, but it may end up costing you more over time compared to a higher-quality pump made with high-grade component materials.

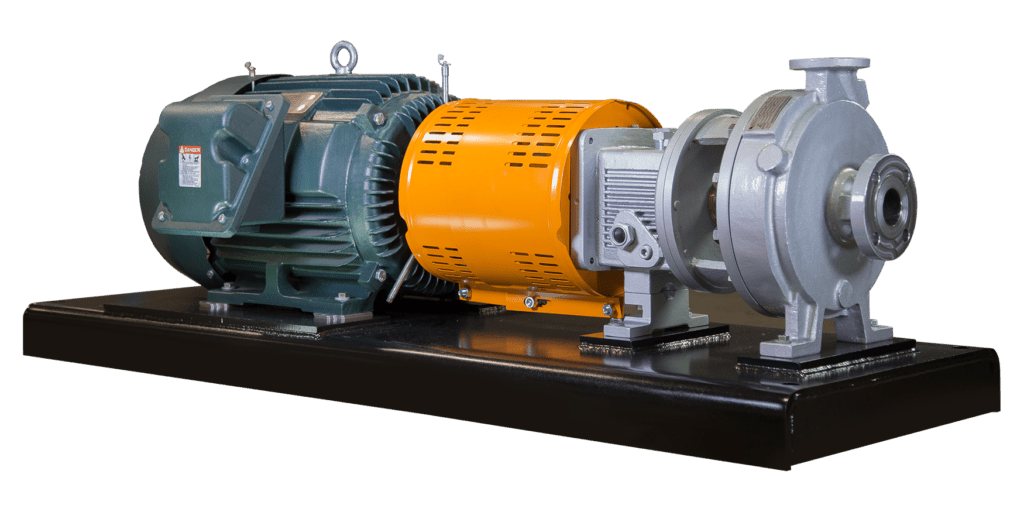

PumpWorks—Built to Last

PumpWorks is a leading manufacturer of high-quality industrial pumps. They use only the exceptional carbon steel in the construction of their process pumps. They are designed for reliability and durability, with minimal downtime and maintenance required to keep them running for a long time. Quite simply, PumpWorks pumps and components are built to last!

To learn more about PumpWorks pumps or for help in finding the ideal pump and pump component material for your specific industrial application, contact Cortech Engineering today.