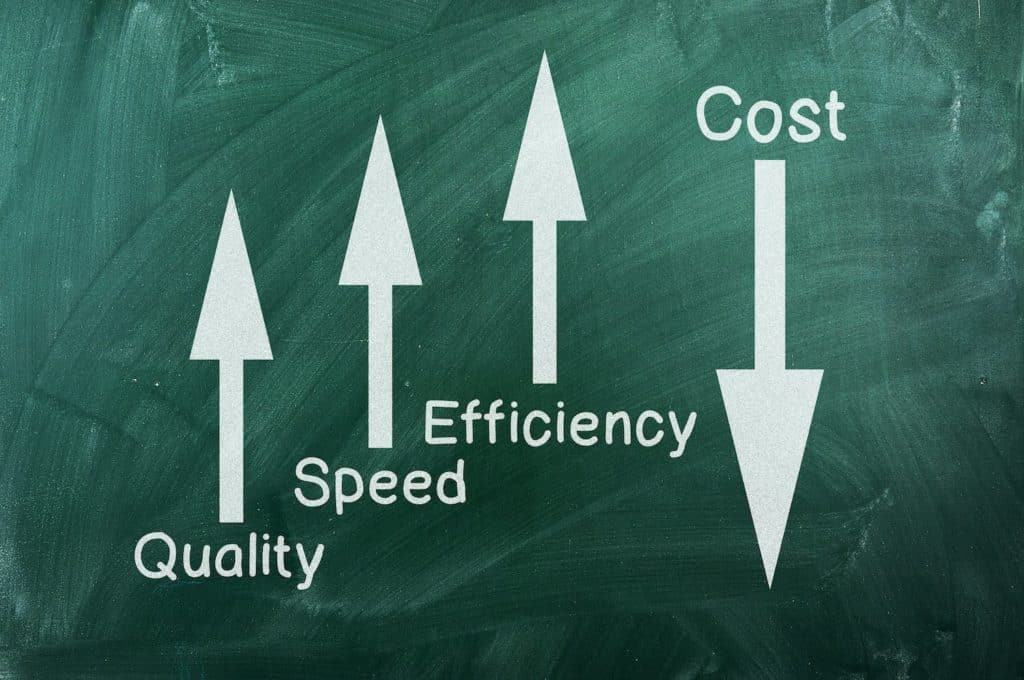

We always want to make things more efficient. We want them to work faster, cost less, and be better for the environment. If this is how you want your business to be running, one of the best things you can do to ensure this is be sure that all of your pumps are as efficient as possible. Thanks to Pumps & Systems, we are able to share this list of tips to help make certain that all of your pumps are in the best working order as they can be to give you the best efficiency in your application.

- Check your application’s life-cycle cost and energy usage. This tip is a great one to follow for both new systems and current systems that need an update. If you are in the market for a completely new system, it would be wise to calculate the life-cycle cost of the application. While newer, more efficient systems seem quite costly up front, they will generally save you a significant amount in day to day costs.

- Monitor your pump’s performance with gauges. Gauges will help you catch an issue early, before it becomes a full blown problem. They can be used at both the discharge and suctions ends of the pump to offer early detection of wear and tear on internal parts or a blockage that may be causing unseen issues.

- Understand the limits of your pump. Some pumps are designed to take on highly corrosive materials and liquids, but some are not. Regardless, the constant flow of abrasive and corrosive liquids through the pump will eventually begin to take their toll on the interior components of the pumps. As they begin to wear, efficiency is lost. Keep your pump’s components in optimal working order for greatest efficiency.

- Use the appropriate size pump for your application. Bigger is not always better, and using a small pump because it costs a bit less can be costly. It may seem like having a pump with higher horsepower will only increase efficiency, but this is not the case. It can actually cause a lot of waste and inefficiency. Be sure to look at the flow rate and discharge pressure that is needed for your application and buy a pump accordingly.

- In addition to the proper size pump, the proper size piping is just as important. The reason the pipe size is important is because it needs to be a diameter that will not allow for sedimentation or settling of slurries. Both of these things will cause inefficiency and blockages in your application.

Cortech believes that a properly functioning pump can make the entire application. It will run more smoothly and more cost-effectively when all parts are in working order and running their best. It is sometimes difficult to determine when a problem can occur, so the best thing to do is conduct routine inspections and maintenance to catch small issues early. Next time, we’ll look at five more ways to keep your pumps running efficiently.