Oil and other high-viscosity liquids can present a unique challenge for many pumps. Operators who regularly deal with viscous materials prefer gear pump systems because they handle difficult fluids more efficiently and effectively. Gear pumps are often found in applications like oil and gas, industrial, mining and aggregate, water and wastewater treatment, municipal, and food and pharmaceutical industries.

How Gear Pumps Work

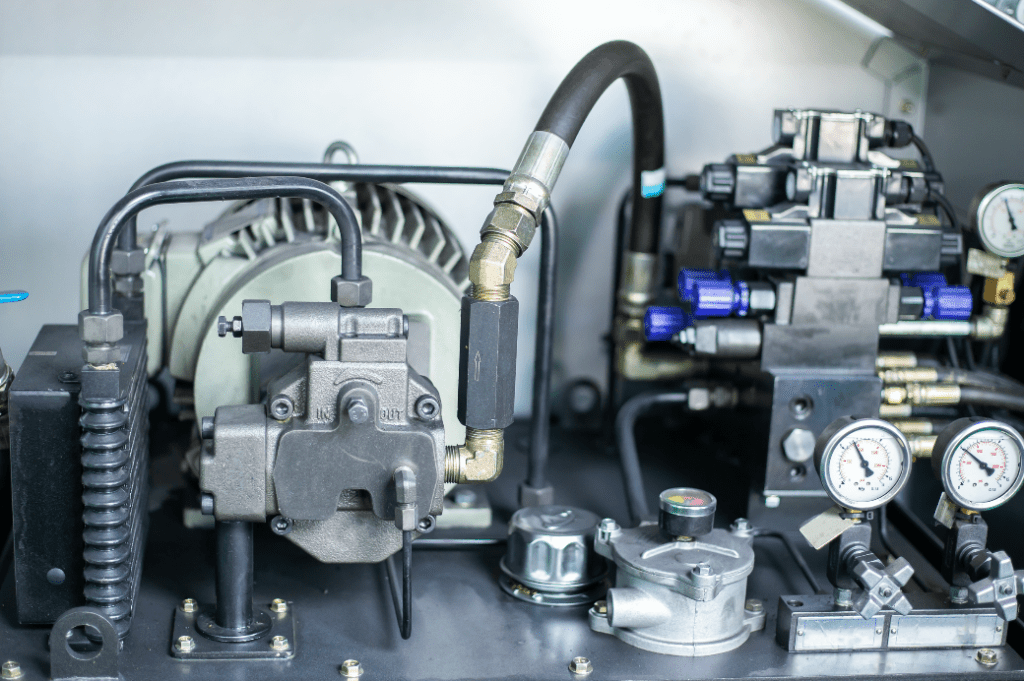

A gear pump is a type of positive displacement pump where, as the name implies, a gear system is used. The motion of the rotating cogs and gears creates a liquid seal, which then generates suction at the pump inlet. The fluid is enclosed within rotating gear cavities before discharging from the outlet port.

A gear pump’s simple design—compact and with fewer moving parts than other pumps—is what makes it ideal for viscous liquids. While they don’t offer high flow rates or produce extreme high-pressure output like a centrifugal pump, they will generate higher pressure than standard vane or lobe pumps. Gear pumps are self-priming and can dry-lift. However, keeping the gears running smoothly depends on lubrication from the pumped fluid, so running them dry for extended periods is not advised.

Types of Gear Pumps

There are two primary types of gear pump designs:

External Gear Pump

An external gear pump uses two identical, interlocking gears supported by separate shafts. In most external gear pumps, the motor drives one gear, which then controls the other. Some pumps, however, have both gears driven individually. The tight tolerances between the gears and the casing produces the suction power. External gear pumps can sustain higher pressures and greater flow rates than internal gear pumps, yet they generally have lower suction capabilities.

Internal Gear Pump

An internal gear pump also uses two interlocking gears. However, its gears are different sizes and one rotates within the other. The rotor is the larger gear, its teeth projecting inward; the idler is the smaller gear inside with external teeth. The idler is mounted off-center and a fixed, crescent-shaped spacer acts as a seal between the inlet and outlet ports. The higher the viscosity of the liquid being pumped, the greater the likelihood an internal gear pump will be necessary.

Gear Pumps at Cortech DXP

Cortech DXP carries internal and external gear pumps in a wide variety of sizes, materials and flow rates. We represent the world’s top gear pump manufacturers, including Liquiflo, PSG Blackmer and Nomad/JDA Global.

To learn more about the advantages of gear pumps and to find the best pump for your operation’s viscous material pumping needs, contact Cortech DXP today.

- Burlingame Engineers

- Cortech Engineering

- Turbo Machinery

- Turbo Machinery

- Burlingame Engineers

- Cortech Engineering