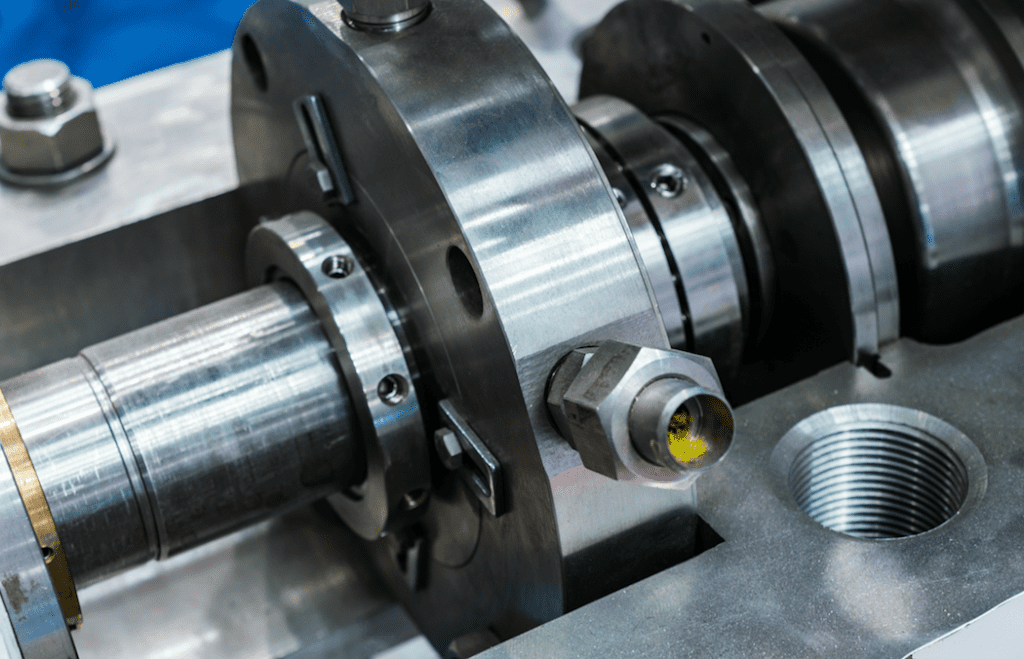

When it comes to pumping bearings or rolling element bearings, proper lubrication is absolutely vital. It minimizes friction, prevents wear and dissipates heat. Without lubrication, the bearings will fail and can cause failure to the pump. Here are some of the key goals of bearing lubrication:

- Support loads with good lubricating film strength

- Maintain stable viscosity, regardless of temperature

- Provide a long service life with a stable structure

- Create a barrier against moisture and contaminants

- Prevent leaks out of the bearing

There are several common types of rolling element bearing lubrication that you can use. It’s important to understand your bearing systems and select the right type of lubrication to achieve the best possible results. This guide from Cortech Engineering should help, so let’s look at the different options:

1. Grease

Grease lubrication requires simple maintenance but provides limited heat dissipation and can lead to over-pressurization within the bearing. Grease lubrication is best suited for pumps with lower horsepower and operating speeds.

2. Oil Bath/Splash

With an oil bath or oil splash lubrication, you will benefit from handling a wider range of speeds compared to grease. You can also see the oil level in some cases, and that helps with maintenance. The disadvantages, however, are that the bearings can be sensitive to the oil level and the oil bath itself can retain contaminants. In addition, the oil can and will evaporate over time.

3. Oil Mist

Rather than an oil bath, you may also consider mist-based oil lubrication, which is applied with an oil aerosol into the bearing housing. This method allows for lower oil consumption, but it takes more training to apply and maintain.

4. Solid Films

There are also solid, non-fluid coatings that can be applied to the friction surfaces that will prevent wear and tear. Most operators would consider this a last-case option in extreme situations where the oil or grease lubrication cannot survive. Examples might include environments with high temperatures, radiation or vacuums. Most solid film lubrication care engineered for specific applications, which means they will also cost more to use.

When it comes to lubricating pump rolling element bearings, it’s important to make the right decision based on your pump, your operational demands and your maintenance needs. For help with your pump bearings and lubrication systems, contact Cortech Engineering today for the assistance and answers you need. We’ll help you get the right type of lubrication for your system.