Compression packing has been around just about as long as mechanical pumps have existed. This process is still used in today’s equipment to prevent loss of process fluids into the environment. Like most things in the industrial pump world, compression packing is not without challenges. If components aren’t monitored, maintained and repaired as needed, compression packing failure will lead to expensive downtime. Knowing how to identify problems with compression packing is key to avoiding these problems.

How Compression Packing Works

A compression packing seal incorporates a packing ring that is set into a stuffing box, which tightens during operation to compress the packing between the stuffing box wall and the shaft. Lubricants built into the packing release as gland pressure is applied. Once in operation, process fluids tend to replace the function of the packing’s built-in lubricants. Over time the packing lubricant is lost, making new packing necessary. Compression packing failures occur if it is not maintained or replaced in time.

Signs of compression packing failure include:

• Increased process fluid leakage

• Smoke from the stuffing box

• Uncontrolled leakage at the gland

• Power loss

• Shaft/sleeve abrasion caused by friction

• Poor gland pressure

Packing Maintenance

Good maintenance is crucial to keep a compression packing system from failing. This will involve replacing worn packing rings and making sure the built-in lubricants are there and functioning properly. How often these steps need to be taken may vary from pump to pump and operation to operation, with particular consideration for the materials in the compression packing itself.

Unfortunately, most pumps will not experience any major compression issues until the packing fails. Most maintenance and repairs should be done preemptively. If not, you run the risk of major downtime when a compression packing failure leads to significant degredation of pump performance or damage to other internal pump components.

A trained pump expert with experience in compression packing often acts like a detective to identify the source of problems as they occur and to recognize potential problems before they happen. It’s not easy work: every component and piece must be examined together to understand how a failure happened so the right repairs and maintenance plan can be made.

Remember “STAMPS”

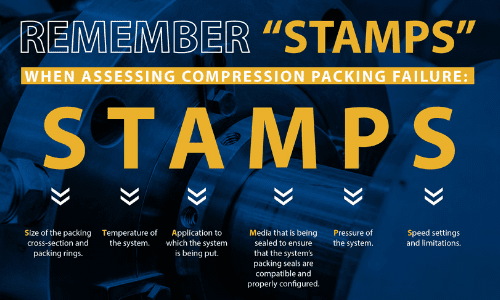

Think of the acronym “STAMPS” when assessing compression packing failure:

• S – Size of the packing cross-section and packing rings.

• T – Temperature of the system.

• A – Application to which the system is being put.

• M – Media that is being sealed, to ensure that the system’s packing seals are compatible and properly configured.

• P – Pressure of the system.

• S – Speed settings and limitations.

Controlling, monitoring and maintaining compression packing is difficult, which is why it pays to work with a knowledgeable guide that can help you configure the pumps in your operation and provide a custom maintenance plan. Contact Cortech today to learn more about how we can help you avoid compression packing failure and get the most out of your pump equipment.