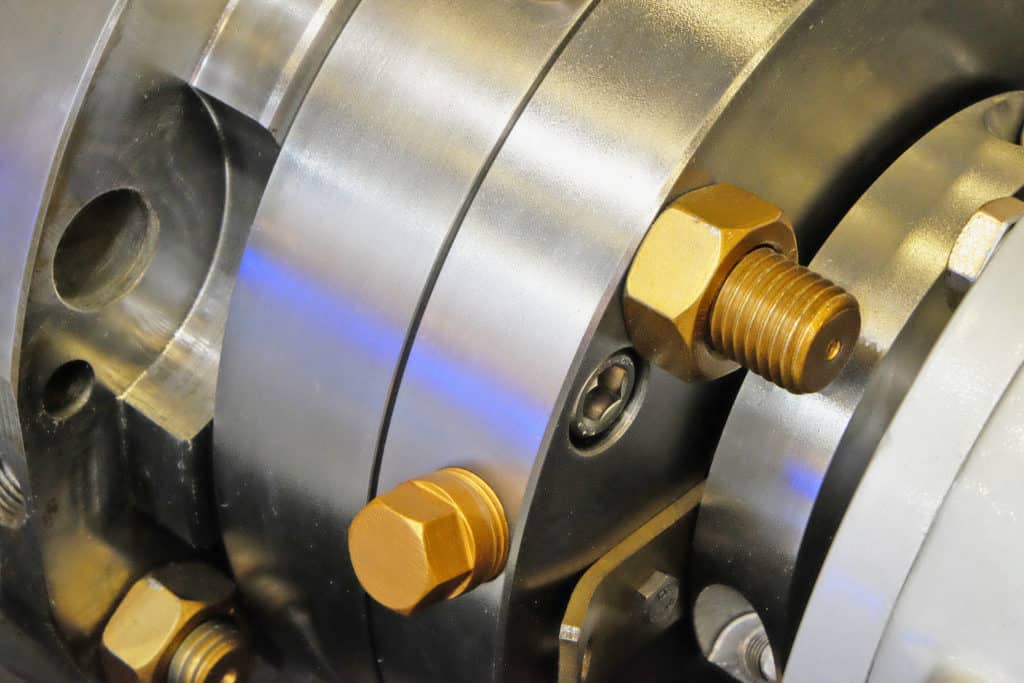

Mechanical seals are very important in pumps. There are various types of mechanical seals that perform specific functions within a pump. Keeping these seals in good working order is crucial for pump efficiency and equipment longevity. Maintaining proper seal balance is one of the key features of any good maintenance program.

What is Mechanical Seal Balance?

When it comes to the performance and health of mechanical seals, a word you may hear often is “balance.” Achieving balance is key to achieving correct seal configuration.

In technical terms, seal balance is the ratio of the closing area (designated as Ac) and the opening area (designated as Ao) in the seal. An imbalance occurs when pressures on different parts of these areas cause the ratio between them (Ac/Ao) to exceed 1:1. The source of pressures on seal parts—whether they are internal or external to the seal—as well as the variability and direction of pressure depend on the type of seal and its role in a system.

Typically, the goal is to find the right ratio of balance depending on the pump and the function of the seal itself. Setting proper balance is a very delicate process because you want to have a seal that provides a requisite closing force without providing too much force and causing heat or unnecessary wear. When this happens leaks occur, equipment is damaged and production time is lost due to repairs.

A New Method for Better Balance

Engineers have come up with a new and somewhat unconventional way to achieve an ideal balance in mechanical seals. Rather than balancing the closing force, the focus is on enabling the opening force. Closing force still needs to be factored in, but adjusting the opening force gives the user more flexibility to adjust and dial in a correct balance.

An example of this can be found in dry gas seals (DGS), which are often used in compressors. These are designed to provide an opening force at the seal faces using an aerodynamic bearing principle. Fine pumping grooves create pressure on the process side of the seal and form a non-contact fluid film bearing. This aerodynamic bearing layer becomes thinner (but not stiffer) as the closing force on the faces goes up.

This kind of seal balance allows the operator to leverage against excessive heat generation. If the seal is starting to run hot, external pressure can be applied to increase the pressure of the seal face. The gap then proportionally increases while the heat shear decreases. This process can also increase reliability of the mechanical seals.

Other Factors Affecting Balance

Other factors that need to be taken into consideration in when balancing seals include:

- Compensation – There are different forms of compensation (orifice, groove, step and porous) that enable bearings and seal faces to run closely together without actually touching.

- Bearing Materials – The bearing materials will also make a difference. Some materials like graphite, carbons and ceramics are naturally porous.

To learn more about balancing mechanical seals and configuring bearings and seals for the best performance and durability in your equipment, contact Cortech today. We know what it takes to get the most out of your pumps and pump systems.