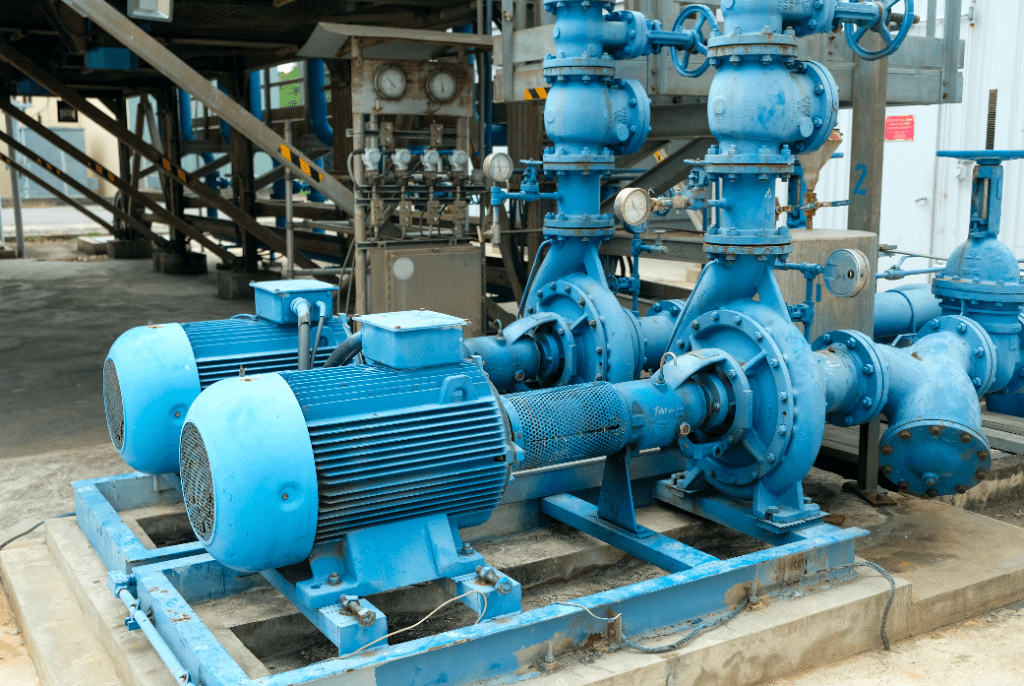

When you need the best performance and longevity from a pump, installation on a level surface is critical. Each pump component must be aligned carefully to achieve the desired results over the life of the pump. Pumps set at improper levels are a common problem we see when out in the field repairing pumps installed by third parties.

It’s as simple as this: Start with proper installation and configuration, and you’ll enjoy the best possible performance from your pumps.

Here are six tips for setting your pump base at the proper level, according to the expert engineers and mechanics at Cortech DXP:

- Remove the Equipment

Whether making repairs or completing a new installation, you’ll achieve the best leveling results by removing all pump equipment from the base plate and the foundation. Starting with all parts dismantled will allow for proper setup—from the foundation up. Neglecting this step can often lead to more problems in the future.

- Build a Solid Foundation

Most industrial pumps are mounted on a concrete foundation. If the foundation is weak, unlevel, or compromised in any way, pump problems are likely. Ensure the foundation is strong and provides a level base from which to start your pump installation.

- Having the Right Base Plate

Between the pump and the foundation is a base plate. A plate that is designed to securely mount your pump is key. If the base plate is not level or has too much flexibility during installation or operation, the pump’s performance or longevity may suffer.

- Properly Machined Mounting Surfaces

Surfaces on which pump components—like the motor and pump housing—will be mounted often contain dirt, grease, paint, welds, or powder coating. It is critical that these surfaces are machined down to bare metal to avoid variables that can adversely affect alignment. Remove all paint or other materials and ensure these surfaces are perfectly level before mounting any equipment.

- Use the Right Tools

Equipment as large and as sensitive as industrial pumps requires equally sensitive leveling tools. Our mechanics use top-of-the-line levels that measure with incredible precision. Installing a pump at the proper level is not a situation where “close enough” will cut it. True precision is imperative, and using the right tools will make all the difference.

- Make it Tight and Secure

When completing an installation, make sure each nut and bolt is tightened properly. Maintain perfect alignment with all key components. Checking all connections and mounts is a key part of ongoing maintenance. Components that become loose or unlevel can lead to eventual pump damage.

Watch this quick video we put together about Setting Pump Bases.

To learn more about our installation process and repair services at Cortech DXP, and for tips on how to set up your pump equipment for optimum performance and reliability, contact us today. You can also visit our website to browse our extensive pump products and user resources.