Cavitation is one of the most common and destructive problems in pump systems. Left unchecked, it can quickly erode critical components, reduce efficiency and shorten equipment lifespan. Understanding how cavitation occurs, recognizing the warning signs and implementing the right countermeasures are essential for protecting your pumps and maintaining reliable operations.

What Is Cavitation?

Cavitation occurs when the pressure inside a pump drops below the vapor pressure of the liquid being pumped. This causes small vapor bubbles to form within the fluid. As these bubbles move into higher-pressure zones within the pump, they collapse violently. Each implosion releases a shockwave strong enough to pit and erode metal surfaces. Over time, this repeated damage compromises pump performance and can result in catastrophic failure.

How Cavitation Damages Pumps

The destructive power of cavitation is both mechanical and operational:

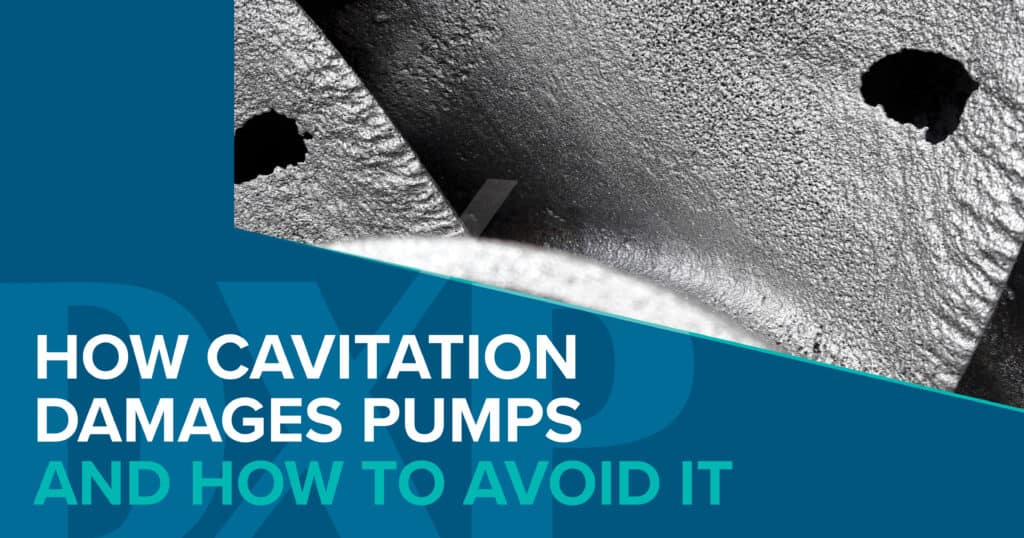

- Surface Erosion: Repeated bubble collapse chips away at impellers, volutes and casings, leaving behind a rough, pitted surface.

- Efficiency Loss: Damaged surfaces disrupt fluid flow, reducing pump capacity and overall hydraulic efficiency.

- Vibration and Noise: The implosions create a distinctive rattling or “gravel” sound and induce vibrations that can harm bearings and seals.

- Heat Generation: Localized temperature spikes during bubble collapse contribute to material fatigue and accelerated wear.

Unchecked cavitation not only leads to frequent repairs but also drives up energy costs as the pump works harder to overcome inefficiencies.

Detecting Cavitation

Cavitation often begins subtly, making early detection critical. Common signs include:

- Unusual noise – a rumbling, rattling or other rough sounds.

- Excessive vibration – particularly around the impeller and bearings.

- Decreased flow or pressure – a noticeable drop in pump performance.

- Rapid wear on impellers – pitting or erosion visible during inspections.

- Seal or bearing failures – caused by added stress from vibration and misalignment.

Monitoring systems with vibration analysis, acoustic sensors, and thermography can help identify cavitation before major damage occurs.

How to Prevent Cavitation

Avoiding cavitation starts with proper system design, operation and maintenance. Key strategies include:

- Maintain adequate Net Positive Suction Head (NPSH): Ensure that system NPSH available (NPSHa) always exceeds the pump’s NPSH required (NPSHr). This may require lowering pump speed, reducing fluid temperature or increasing suction head pressure.

- Optimize pump selection: Choose pumps designed for the specific fluid properties, flow rate and system pressure. Mismatched equipment increases cavitation risk.

- Reduce suction lift and pipe restrictions: Minimize long suction lines, sharp bends and undersized piping that cause pressure drops before fluid enters the pump.

- Control operating conditions: Avoid running pumps too far from their best efficiency point (BEP), which can create unstable flow patterns.

- Regular maintenance and monitoring: Inspect impellers, seals and bearings for early signs of cavitation damage, and address problems quickly to prevent escalation.

In some applications, using hardened materials or specialized coatings on impellers can also extend pump life in environments prone to cavitation.

Protecting Your Pumps with the Right Expertise

Cavitation is a silent killer of pumps, but it doesn’t have to derail your operations. By designing systems with proper suction conditions, monitoring performance and addressing early warning signs, you can safeguard your equipment and avoid costly downtime.

At DXP Pacific, our team specializes in diagnosing and solving cavitation issues across industries. Whether you need help with pump selection, system redesign or advanced monitoring, we provide the expertise and solutions to keep your pumps running reliably.