Nearly half of the costs associated with breakdowns of rotating machines are related to shaft misalignment. Important and expensive components can wear out more quickly and cause a lot of downtime. Overall, equipment will suffer and won’t last as long if any shafts are not in complete alignment. Some of the most common issues associated with shaft misalignment include:

- Increased seal lubricant leakage

- Increased friction and wear

- Excessive energy consumption

- More downtime for repairs

- Costly parts replacements

- Failure of bearings, seals, bolts and couplings

- Excessive vibrations and noises

- Decreased lifespan of machinery

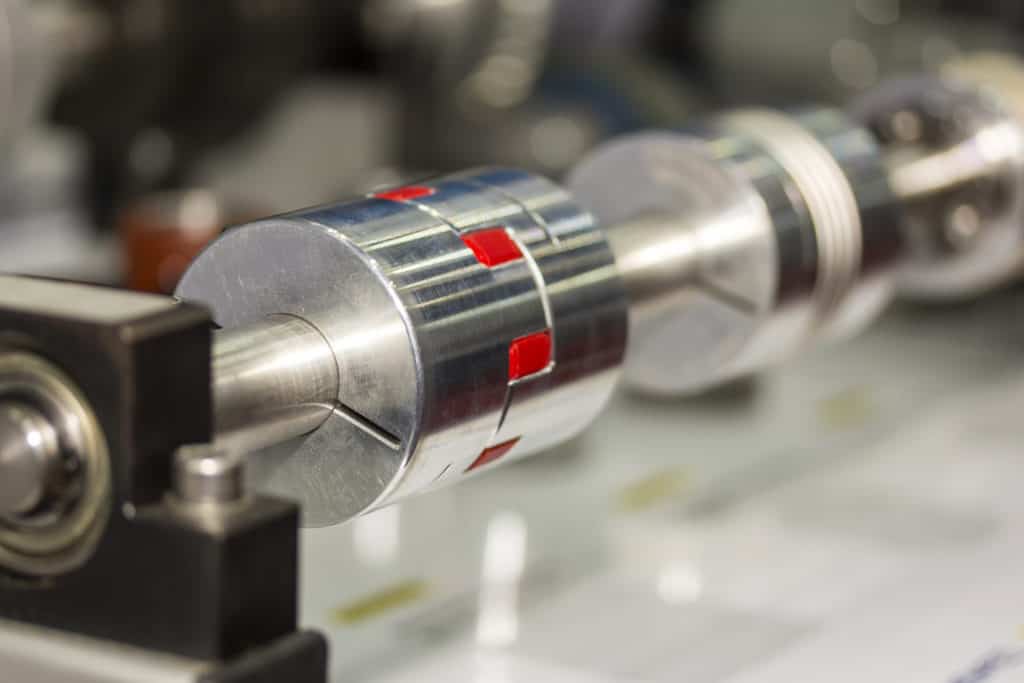

Shaft Alignment Testing

Remember that alignment typically involves more than one shaft. Throughout any given equipment system, there are usually multiple shafts that all need to be in perfect alignment with one-another and with the components they are connected to. Alignment needs to be checked thoroughly as machines are installed and should be tested regularly.

Shaft Alignment Training

The need for ongoing testing is why it’s so important to have shaft alignment training as part of your operation. Anyone working with the equipment should first understand the importance of proper alignment and be able to troubleshoot if there are any signs of misalignment. At Cortech, we see too many organizations take a reactive approach to shaft alignment—meaning they wait until problems occur and then spend precious time and money dealing with downtime and repairs.

Shaft alignment training allows your operation to take a more proactive approach to machine maintenance. Arming your employees with knowledge is always helpful. Checking and adjusting alignment as part of a routine maintenance plan will help prevent problems.

Types of Shaft Misalignment

There are three types of misalignment to look for:

- Angular Misalignment—This usually happens when the motor is being fitted and the shaft is not completely aligned with the driven equipment. Misalignment here will cause damage to the equipment and to the motor itself.

- Parallel Misalignment—This happens when you have two centerlines that are parallel but are not in the same line. Any displacement or variations in alignment will cause problems.

- Combination Misalignment—The worst case scenario is when you have a combination of parallel and angular misalignment.

Contact Cortech today for help with shaft alignment maintenance and training programs. Our goal is to help you get the most out of your pumps and other heavy machinery, so let our engineering experts guide you in the right direction.