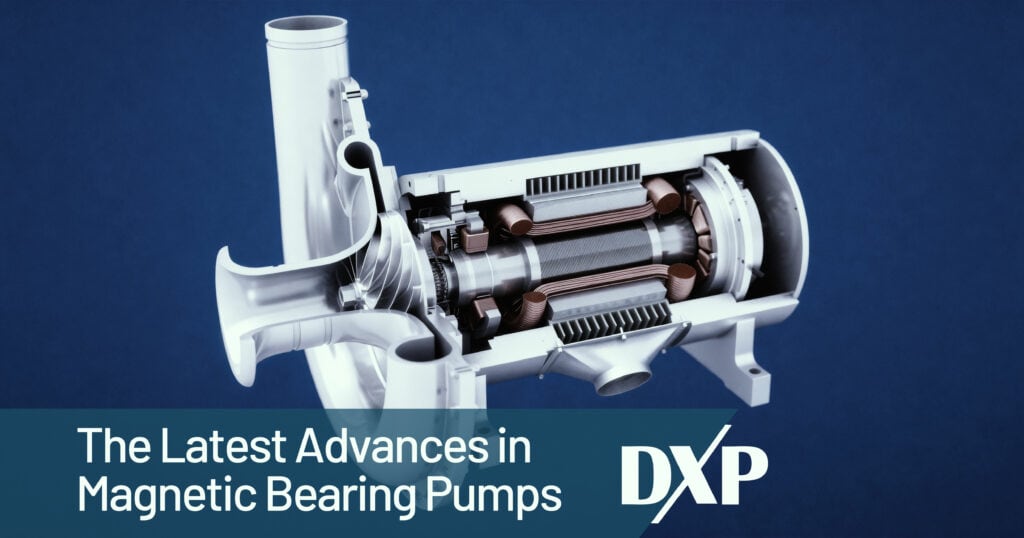

Magnetic bearing pumps are redefining what’s possible in high-performance fluid handling. By suspending the pump shaft using controlled magnetic fields rather than physical bearings, these systems eliminate mechanical contact between rotating and stationary components. The result is a frictionless, oil-free operation that delivers exceptional reliability, precision and efficiency.

As industries push for greater performance, cleaner operations and lower maintenance demands, magnetic bearing pumps are finding their place in more critical applications. They are designed to handle a wide range of fluids, from chemical processing to power generation and semiconductor manufacturing.

How Magnetic Bearings Work

In a traditional pump, mechanical bearings support the rotating shaft. This creates friction and requires lubrication. Over time, this contact leads to wear, vibration and eventual bearing failure.

Magnetic bearings replace that contact with electromagnetic force. Using a network of sensors and control coils, the system continuously monitors shaft position and adjusts magnetic fields in real time to keep it centered within microns. The result is near-zero friction and no need for lubrication systems.

Two primary types are used in pumps:

- Active magnetic bearings (AMB): Employ feedback-controlled electromagnets to dynamically stabilize the shaft.

- Passive magnetic bearings (PMB): Use permanent magnets for simple, fail-safe support in low-speed or backup roles.

Key Advantages of Magnetic Bearing Pumps

- No Mechanical Wear: With no physical contact, there’s virtually no wear on rotating components. This significantly extends service life.

- Oil-Free Operation: Eliminates contamination risks and maintenance associated with lubricating fluids.

- Reduced Vibration and Noise: Active control systems ensure smoother operation and lower vibration levels, improving process stability.

- High-Speed Capability: Magnetic systems enable higher shaft speeds and greater energy efficiency in demanding applications.

- Real-Time Monitoring: Integrated sensors continuously report operating data, allowing predictive maintenance and remote diagnostics.

These benefits make magnetic bearing pumps ideal for environments requiring extreme cleanliness, precision and uptime.

Current Limitations and Design Considerations

While the technology continues to advance, magnetic bearing systems aren’t without challenges.

- Higher Initial Cost: Advanced control electronics and specialized materials make these pumps more expensive upfront.

- Complex Controls: They require precise monitoring and power management, often supported by redundant systems.

- Limited Suitability: For simple, low-duty applications, mechanical bearing designs remain more cost-effective.

However, as manufacturing techniques improve and digital controls become more affordable, magnetic bearing pumps are becoming increasingly practical for a wider range of uses.

Ideal Applications for Magnetic Bearing Pumps

Magnetic bearing technology is particularly well-suited for:

- Chemical and Petrochemical Processing: Where contamination-free operation is critical.

- Power Generation and Turbo Machinery: For handling high-speed compressors and circulation pumps.

- Cryogenics and Vacuum Systems: Where conventional lubrication is impossible.

- Semiconductor and Pharmaceutical Manufacturing: Demanding ultra-clean, vibration-free conditions.

DXP Pacific partners with industry-leading manufacturers to supply and integrate magnetic bearing pump systems that meet these exacting requirements. We help you find solutions that provide precision performance with long-term reliability.

The Future of Frictionless Pumping

As control systems become more intelligent and digital twins enable predictive performance modeling, magnetic bearing pumps are poised to play a growing role in high-efficiency, low-maintenance industrial systems.

With DXP Pacific’s engineering expertise and access to the latest technologies, we help customers explore advanced pump solutions that balance innovation, efficiency and operational dependability. Contact us today to learn more about the latest magnetic pump systems and how we can help your operation with performance and durability.