Filter-press pumps are highly effective and often used for many applications that require solids, slurries or sludges to be separated from liquids. They are common in wastewater treatment, chemical processing, and various other industries.

It’s easy to understand why a filter-press pump would be recommended for this type of processing, but there are numerous factors you will need to consider when selecting the right filter-press pump for your specific application.

Cortech Engineering has put together this list of factors to consider when choosing the right filter-press pump:

- Make Sure to Have the Right Pressure

Most filter-press pumps operate between 8 and 15 bar and will need to distribute the pressure evenly for the best results. You will want to have a pump that can handle your particular separation process and provide the consistent pressure that is required.

- Secondary Pumps May Be Required

In order to operate a filter-press pump, different systems of displacement pumps are commonly used in conjunction to build the amount of pressure needed. Depending on the size of your plant and the processing that needs to be done, it’s important to have the right overall system designed.

- Hose-Diaphragm Piston Pumps

The hose-diaphragm piston pump is one type of filter-press pump that has simple electrical operations while generating strong pulsation. However, it will require constant lubrication which can make installation/maintenance costs quite high.

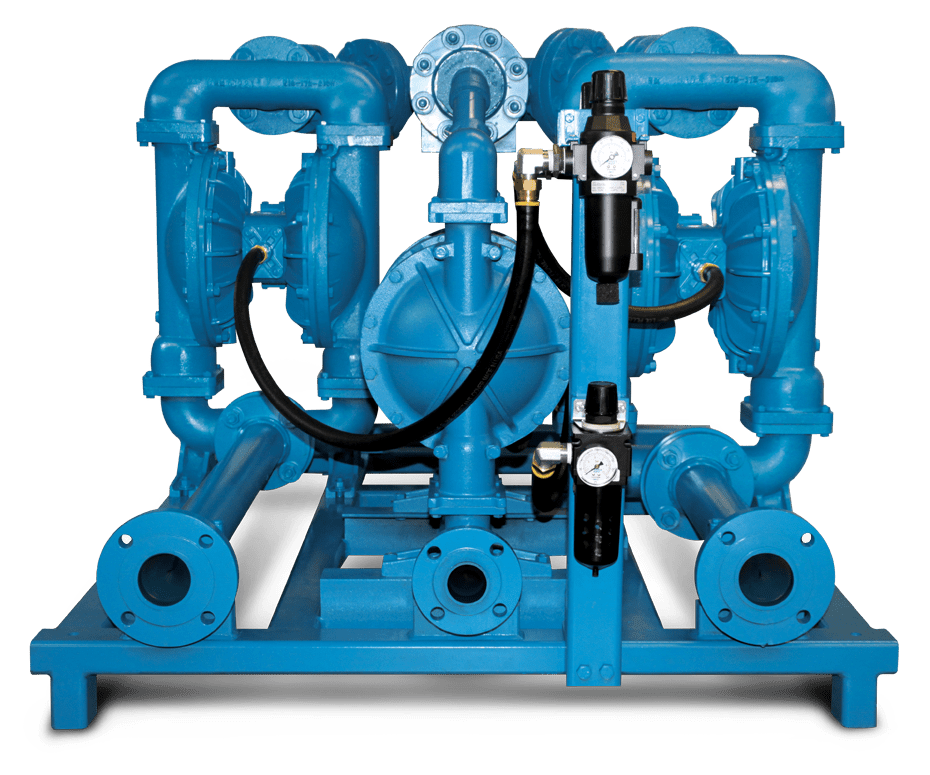

- Air-Operated Double-Diaphragm Pumps

AODD pumps are probably the most commonly used pumps for filter-press applications. They are resistant to dry running and require little maintenance because they are self-priming, self-regulating and highly compact.

- AODD Variants

If you are using an AODD pump for filter-press applications, it’s important to understand certain variants. Some systems will use one of the two diaphragms to generate the necessary additional pressure, but it leads to high pulsation, low feed rates, and high air requirements. An alternative is to use an internal pressure conversion. The set-up is more complex but very effective for demanding operations that seek performance and durability.

Most experts would agree that AODD pumps are the best option for filter-press operations, but there are still many factors and configurations to consider. For help with your pump system and determining the best filter for your operation, contact Cortech Engineering today. We can find the right filter-press pump for your specific industrial applications.