6 Reasons Why Mechanical Seals Fail

Mechanical seals are critical for any pump system. They prevent catastrophic leaks and contain the extreme pressures and temperatures caused during the pumping process. A good mechanical seal properly installed and maintained can provide many key benefits. The pump equipment will operate more reliably and efficiently. There is less risk of process fluids leaking out […]

6 Tips for Replacing Centrifugal Pump Mechanical Seals

Mechanical seals play a very important role in any centrifugal pump system. They prevent air and fluid from leaking from the critical connection point between the impeller and the casing. Ultimately, this helps maintain proper pressure inside the pump. A healthy mechanical seal is critical to maintaining optimized pump performance and maximizing the equipment’s overall […]

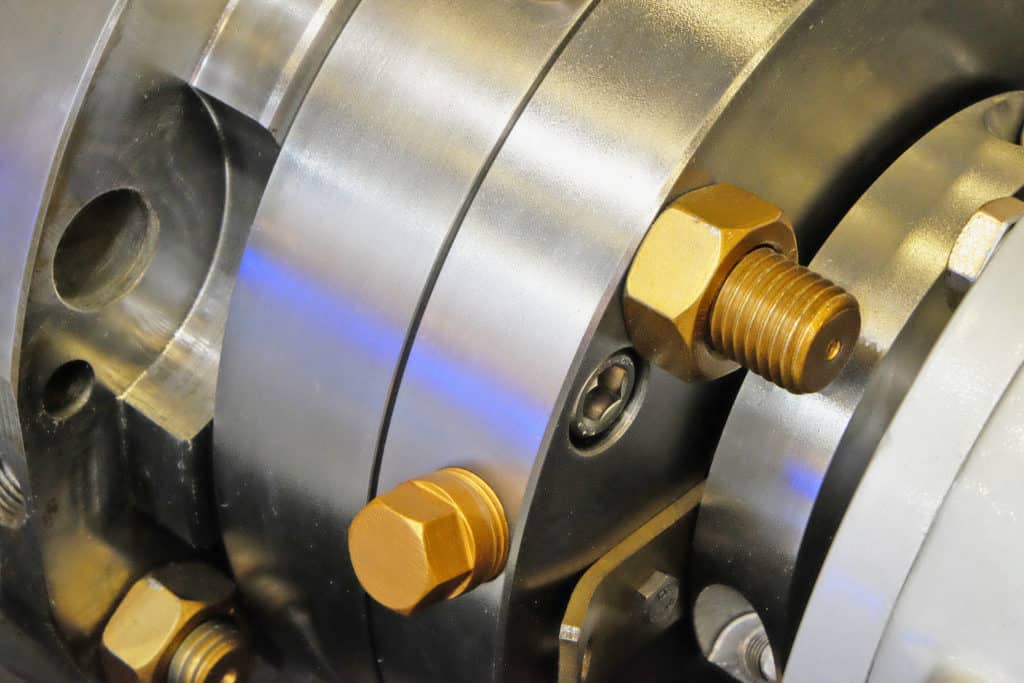

The Importance of Mechanical Seals in Centrifugal Pumps

Mechanical seals are designed to preserve the integrity of the pump system. They prevent fluid leaks and maintain a proper pressure seal within any centrifugal pump. The rotating shaft enters the back end of the pump casing by way of a stuffing box or seal chamber. To achieve better performance, safety, and durability, it is […]

Why You Should Match Your Seal to Your Application

Numerous types of seal technology can be used in pumps and other rotating equipment. From simple seals to very complex mechanical seal designs, there are various options to understand and consider for your pump system. One factor that you must review is your processing application. The types of fluids or materials you are moving, flow […]

Don’t Settle for Substandard Mechanical Seals

Mechanical seals are a vital component of rotating equipment like pumps, agitators, compressors, and mixers. When moving parts are involved in fluid processing, a proper mechanical seal will prevent leakage. Improperly sealed machines can also allow outside elements to seep in, potentially damaging equipment or compromising process fluids. Precise Fit and Function Rotating equipment features […]

Extend Pump Life with These Mechanical Sealing Options

Mechanical seals prevent leaks and the introduction of contaminants between a pump’s rotating shaft and the pump casing. There are many different styles of mechanical seals. They come in all sorts of sizes and configurations to work with different pumps and fluid media. Some are rather simple in design, while others are much more complex. […]

What Seal is Best for Cryogenic Temperatures?

Cryogenics involves the study of how matter behaves at extremely low temperatures. In some cases, these temperatures might approach absolute zero as liquefied gasses, refrigerants, coolants, low-temperature hydrocarbons and other cryogenic liquids are used to create very cold environments with stable chemical reactions. The Challenges of Cryogenic Sealing One of the biggest challenges in […]

An Unconventional Balancing Method for Your Mechanical Seals

Mechanical seals are very important in pumps. There are various types of mechanical seals that perform specific functions within a pump. Keeping these seals in good working order is crucial for pump efficiency and equipment longevity. Maintaining proper seal balance is one of the key features of any good maintenance program. What is Mechanical […]