Why You Should Perform a Vibration Analysis

Predictive Maintenance for Smarter Pump System Management Downtime is a nuisance. It is also extremely costly. Unplanned maintenance and repairs can disrupt operations, reduce productivity, and rack up expenses quickly. One of the most effective ways to stay ahead of mechanical failures is through vibration analysis—a core tool in any predictive maintenance strategy. What Is […]

6 Tips for Pump Seal Support Systems

Mechanical seal support systems are essential to ensure reliable and efficient operation of industrial pumps. These systems provide the necessary environment for seals to function effectively—regulating pressure, temperature, and fluid flow around the seal faces to prevent leakage and premature wear. Properly managing these systems not only extends the life of the mechanical seal but […]

Emergency Pump Support When You Need It Most

DXP Pacific’s On-Call Services Keep You Running 24/7 When a pump system goes down unexpectedly, every minute of downtime can mean costly production losses, safety risks, and increased operational stress. That’s why DXP Pacific offers around-the-clock emergency pump support services to keep your critical operations moving—no matter the hour or the challenge. 24/7 Emergency Pump […]

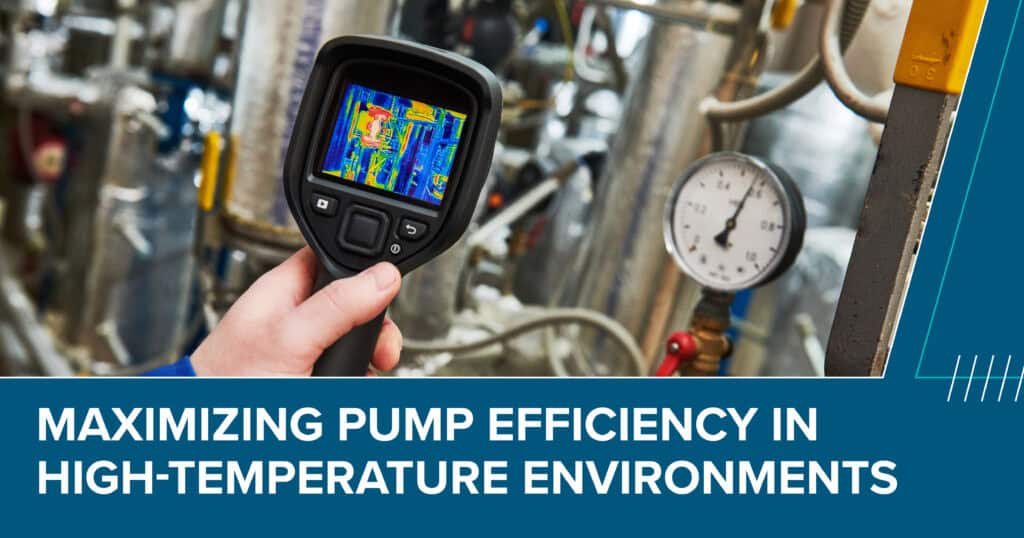

Maximizing Pump Efficiency in High-Temperature Environments

High-temperature environments can pose significant challenges for pump systems. High temperatures can affect equipment performance, reliability, and longevity. Pumps exposed to extreme heat must be engineered, maintained, and operated with precision to ensure optimal efficiency. This guide explores best practices to maximize pump performance in high-temperature settings, including material selection, maintenance strategies, and operational adjustments. […]

Understanding the Total Cost of Pump Ownership

Many companies focus on a pump’s purchase price, but the real financial impact goes far beyond the initial investment. The total cost of ownership (TCO) includes installation, maintenance, energy use, downtime, and eventual replacement. A pump that seems affordable up front can quickly become expensive if hidden costs add up. Understanding these factors helps businesses […]

Pumps in Mining: Meet the Challenges of Harsh Environments

Mining operations rely on efficient pumping systems to manage water, slurries, and chemicals in some of the most challenging environments on the planet. From underground dewatering to abrasive slurry transport, mining pumps must withstand extreme pressures, corrosive materials, and continuous operation. Choosing the correct pump system is critical to maintain productivity and reduce costly downtime. […]

What Is a Transverse Flux Pump Motor?

When it comes to industrial pump system technology, efficiency and precision are key drivers of innovation. Among the cutting-edge advancements is the transverse flux pump motor, a unique solution that addresses the growing demand for specialized pump systems in energy-intensive applications. But what exactly is a transverse flux pump motor, and why is it gaining […]

10 Ways to Extend Pump Bearing Life

Pump bearings are the unsung heroes of efficient, reliable industrial operations. These critical components support rotating parts, minimize friction, and ensure smooth pump operation. Neglecting proper bearing maintenance can lead to costly failures, unplanned downtime, and diminished system performance. This article explores 10 actionable tips to extend the life of your pump bearings to keep […]

How Can Baseline Data Improve Predictive Maintenance?

Predictive maintenance (PdM) is revolutionizing equipment management, particularly in pump system operations. With the ability to foresee potential issues before they cause costly downtime, predictive maintenance helps businesses optimize performance, extend equipment life, and reduce operational costs. Central to this approach is the often overlooked hero: baseline data. This article explores the role of baseline […]

Radial vs. Axial Thrust: The Key Differences

In systems, understanding the forces at play is crucial. Monitoring and managing these key factors can enable you to maintain efficiency, prevent failures, and prolong equipment life. Two critical forces that every pump operator and engineer must grasp are radial thrust and axial thrust. These forces have a direct effect on your pump’s performance and […]

Why Your Pump Is Losing Prime and How to Fix It

When a pump loses prime, it stops functioning correctly. This leads to inefficiencies, potential equipment damage, and costly downtime for repairs. Maintaining prime ensures consistent fluid movement and prevents issues like cavitation or overheating. In this article, we’ll explore common causes of lost prime and how to troubleshoot and fix them. What Is Pump Priming? […]

Optimize Chemical Processing with Custom Pump Selection

Chemical processing operations depend on precision, reliability, and efficiency. At the core of these operations are pumps that handle everything from aggressive chemicals to high-viscosity fluids. Choosing the right pump is critical—not only to optimize performance but also to ensure safety, reduce downtime, and extend equipment lifespan. With custom pump selection and system configurations, chemical […]