6 Reasons Why Mechanical Seals Fail

Mechanical seals are critical for any pump system. They prevent catastrophic leaks and contain the extreme pressures and temperatures caused during the pumping process. A good mechanical seal properly installed and maintained can provide many key benefits. The pump equipment will operate more reliably and efficiently. There is less risk of process fluids leaking out […]

5 Mistakes to Avoid During Pump Installation

Pumps can fail for several reasons. Many failures happen during operation. The equipment can sometimes be at fault. So can the operator, especially when proper maintenance isn’t performed. You have full control of the equipment and can prevent many system failures at one point in the process. We’re talking about pump installation. Taking the right […]

Reduce Shaft Seal Leakage with These 6 Steps

Shaft seal leakage can be a serious problem with pump equipment. Hazardous material could leak into the environment, or outside contaminants could compromise your process fluid. A leaking shaft seal can also lead to poor equipment performance and additional pump damage if left ignored. It is important to address any detected leaks immediately to avoid […]

5 Ways to Minimize Pump Downtime

Every pump system will require some downtime for general maintenance, replacing parts and making repairs. It’s inevitable you will have to shut the equipment down from time to time. The key is to minimize how much downtime is required. This will increase uptime with a more efficient and productive pump system. So, how do you […]

How Fluid Viscosity Affects Your Pump System

There are many different types of fluids being pumped throughout the world every single day. From clean water to thick slurries and everything in between, every type of liquid will flow through its respective pump system differently. Fluid viscosity is one of the most important factors to consider when selecting pumps and configuring a system […]

What You Need to Know About Submersible Water Pumps

Many industries rely on submersible water pumps, which are designed specifically to pump out liquid from a fully submerged state. These portable pumps are ideal for dewatering at mines, construction sites, industrial sumps, and other applications where there is a critical need for efficient dewatering. How Do Submersible Water Pumps Work? Submersible pumps are similar […]

5 Tips for Pumping Corrosive Liquids

Pumping corrosive liquids, abrasive materials, hazardous fluids, and harsh chemicals presents many challenges. Corrosive liquids degrade, damage, and even destroy specific pump system components. In addition, certain metals, plastics, and glass can experience significant corrosion when pumping these fluids and chemicals. There are several concerns when it comes to pumping corrosive liquids. First, your equipment […]

Sealless Magnetic Drive Pumps from ANSIMAG & HMD Kontro

Sealless magnetic drive pumps are very popular in the chemical processing industry. The sealless technology eliminates leak risks, which are crucial in chemical transfer applications. These pumps do not have seals that can wear out with time or be compromised because of excess heat, pressure, corrosion, or other challenging operating conditions. Therefore, the dangerous chemicals […]

Discover the Sludge-Pumping Power of Vogelsang

Vogelsang has been a leading company in the pump industry for over 90 years. They have created many advancements in pumping, maceration, spreading, and biogas technology. Numerous industries use Vogelsang pumps with a special focus on wastewater operations. About Vogelsang Vogelsang manufactures dependable products to handle abrasive sludges and solids, such as specialized rotary lobe […]

Benefits of a Variable-Frequency Drive (VFD)

There are many reasons why you may want to consider installing a variable-frequency drive (VFD) on your centrifugal pump system. Energy savings and operating efficiency offset the costs of adding a VFD—but not all pump systems require VFDs. Therefore, it’s critical to understand how to run your pump most efficiently. This article will help you […]

Your Guide to Pump Lubrication

Pump systems transport various materials, from water and chemicals to slurries and solids. Many different types of pumps use different mechanical processes to create suction and push liquids through the pump. For example, you have centrifugal pumps, diaphragm pumps, screw pumps, progressive cavity pumps, and many others. Each pump and system type will require specific […]

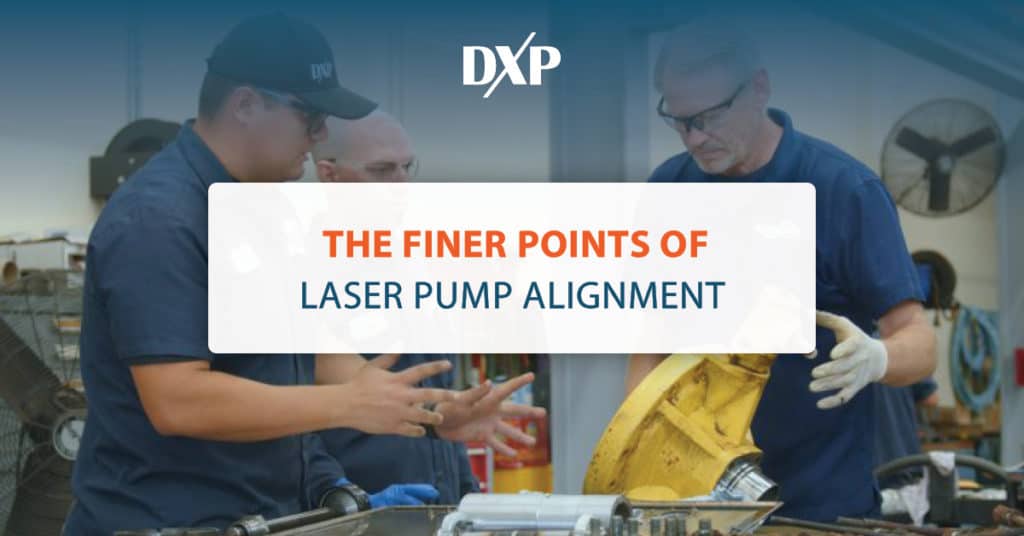

The Finer Points of Laser Pump Alignment

You can achieve optimal pump alignment—technology, technique, and laser alignment being paths to get you there. Keep reading to learn from DXP Pacific’s strategies. Technology and Technique At DXP Pacific, we often utilize old-school manual pump alignment techniques in addition to high-tech solutions like laser pump alignment. Lasers offer unprecedented accuracy and speed, but […]