Benchmarking Pump Performance: Which Metrics Matter Most?

Industrial pump systems are expected to deliver consistent, reliable performance—even under demanding operating conditions. But how do you know if a pump is achieving what it should? That’s where performance benchmarking comes into play. By closely tracking specific metrics, operators can validate correct operation, identify early warning signs of failure and optimize long-term efficiency. Benchmarking […]

Deploying Intelligent Pumps for Automation

In today’s industrial landscape, automation is critical to staying competitive. Smart technologies have transformed many facets of manufacturing and processing operations, and pumps are no exception. Intelligent pumps equipped with adaptive controls are reshaping the way facilities manage fluid movement, energy consumption and maintenance planning. By deploying these advanced systems, companies can reduce operational costs, […]

Integrating IoT Sensors in Pump Monitoring

In today’s data-driven landscape, real-time insight is everything. For pump systems, the integration of IoT (Internet of Things) sensors is revolutionizing the way operators monitor, maintain and optimize performance. These sensors transmit continuous operational data, which can significantly reduce downtime, improve reliability and extend the lifespan of critical pump assets when monitored properly. The Evolution […]

Troubleshooting Vibration and Noise in Pumps

Vibration and noise are often the first signs that something is wrong with an industrial pump system. If left unaddressed, these symptoms can accelerate wear, reduce efficiency and ultimately cause system failure. Operators can keep pumps running smoothly while extending equipment life by understanding the root causes, using the right measurement techniques and applying effective […]

Compliance & Safety Standards for Industrial Pumps

Properly managed pump systems are essential to moving fluids, keeping processes efficient, and protecting people and assets. Beyond performance and reliability, however, pumps must also operate under a framework of compliance and safety standards. These standards are established by international and national organizations. They provide a set of compliance codes designed to protect workers, safeguard […]

Critical Benefits of Routine Pump Lubrication

Lubrication is one of the simplest yet most essential practices in pump maintenance. Whether your facility operates centrifugal, positive displacement or submersible pumps, routine lubrication plays a critical role in ensuring long-term reliability and efficiency. Without it, pumps are far more likely to suffer from premature wear, overheating and unexpected downtime. By establishing a consistent […]

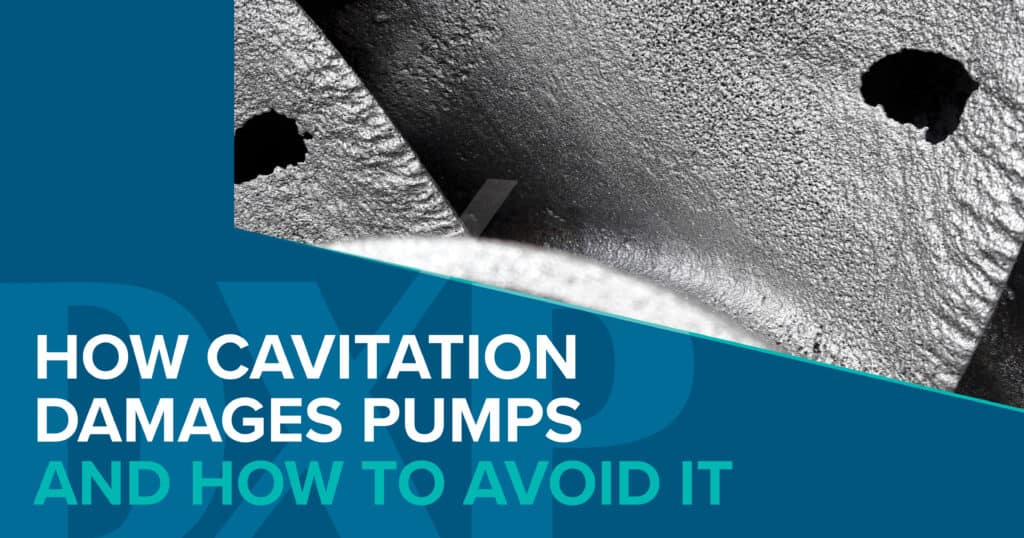

How Cavitation Damages Pumps and How to Avoid It

Cavitation is one of the most common and destructive problems in pump systems. Left unchecked, it can quickly erode critical components, reduce efficiency and shorten equipment lifespan. Understanding how cavitation occurs, recognizing the warning signs and implementing the right countermeasures are essential for protecting your pumps and maintaining reliable operations. What Is Cavitation? Cavitation occurs […]

7 Maintenance Strategies for Submersible Pumps

Submersible pumps are indispensable in industries ranging from municipal water and wastewater treatment to mining, construction and food processing. Designed to operate while fully submerged, these pumps face unique stresses that above-ground equipment does not. They deal with constant exposure to water, abrasive particles, corrosive fluids and challenging operating environments. Without the right maintenance strategies, […]

How Thermodynamic Testing Can Boost Pump Accuracy

When it comes to industrial pump performance, small inefficiencies can quickly turn into big operational headaches. Energy waste, reduced flow rates and unexpected downtime all stem from inaccurate performance measurements. Thermodynamic testing is one of the most reliable methods for pinpointing how well a pump is operating and ensuring systems are running at peak efficiency. […]

6 Signs Your Pump Needs an Upgrade

Industrial pumps are built for longevity, but even the most robust systems eventually show signs of aging, wear, or inefficiency. Waiting until your pump completely fails can lead to unplanned downtime, costly repairs, and production delays. The key to avoiding these consequences is knowing the early warning signs that your pump needs to be replaced […]

8 Keys for Large Pump Motor Maintenance

Large pump motors are essential for the performance and reliability of many industrial systems. Whether driving critical water systems, chemical processes, or oil and gas applications, these motors endure demanding conditions that require proactive care. Effective maintenance not only extends equipment life but also prevents costly downtime and unexpected failures. Below are key strategies to […]

How to Improve Energy Savings in Your Pump System

When it comes to pump system efficiency, every detail matters. Many facility managers and operators focus on selecting the correct pump and motor. However, achieving maximum energy savings often depends just as much on how the system is installed and maintained. One of the most important—and often overlooked—factors is proper alignment. Why Alignment Matters Pump […]