Three Important Differences Between Fluids and Liquids

When it comes to pumps, understanding the differences between fluids and liquids is crucial for optimizing performance and efficiency. These terms are often used interchangeably. However, they have very distinct meanings in an engineering context. Specifically, the characteristics of viscosity, density, and vapor pressure are critical to determine how a substance behaves as it flows […]

Custom Solutions for Specific Pump Challenges

At DXP Pacific, we understand every pump system comes with a unique set of challenges. Whether it’s the fluid processing application, a difficult operating environment, or specific performance requirements, no two pump systems are exactly alike. That’s why we pride ourselves on offering custom solutions that address the specific needs of each of our clients. […]

Optimize Your Pump System with a VFD

Pump system optimization is a top priority for all operators. It’s critical to take every step you can to achieve peak equipment performance and longevity. One of the most effective ways to achieve this goal is to integrate variable frequency drives (VFD) into your pump systems. A VFD is an electronic device that varies the […]

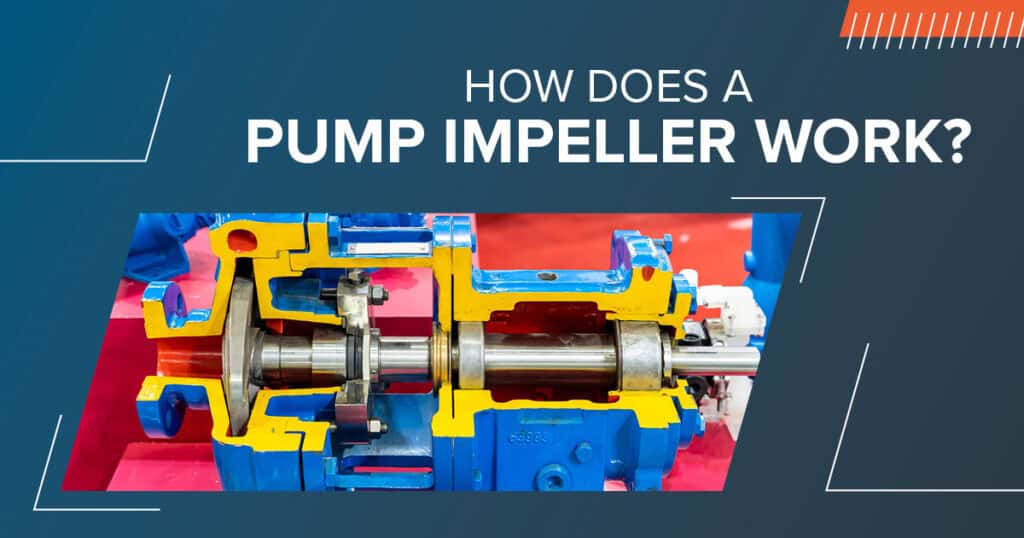

How Does a Pump Impeller Work?

The impeller is a critical component in centrifugal pumps. It is responsible for the efficient movement of fluid through the pump system. As an operator, it is beneficial to understand how the impeller works. In this article, we will explore the impeller’s design, operational principles, and the different types of impellers available. Impeller Basics The […]

Pump Troubleshooting: How to Identify a Seal Leak Source

One of the most common mechanical problems that can arise with pumps is a seal leak. Identifying the source of a seal leak is crucial for maintaining the efficiency and longevity of your industrial or municipal pump system. Experienced operators and engineers know the following steps can be taken to effectively troubleshoot a pump seal […]

Professional Pump Repair from Proven Experts

As a pump operator, you depend on reliable and consistent performance and reliability from your pump equipment. Downtime can be costly, which is why the need for dependable pump repair services is so important. At DXP Pacific, we specialize in providing expert pump repair and maintenance services that keep your systems running smoothly. Our pump […]

How to Select the Right Bearing Isolator

Bearing isolators are essential components that protect bearings on rotating equipment from contamination and leakage. Choosing the right bearing isolator is critical for operators aiming to optimize their pump systems and ensure long-term equipment performance. Below is important information you need to know when selecting the best bearing isolator for your specific pump equipment. How […]

7 Qualities to Look for in a Pump Management Partner

Many important steps go into managing a fully optimized pump system. You have equipment selection, custom configurations, installation, training, maintenance, repair, and aftermarket upgrade needs if you want your pump to perform its best for many years to come. This is why so many companies and municipalities look for a reliable pump management partner to […]

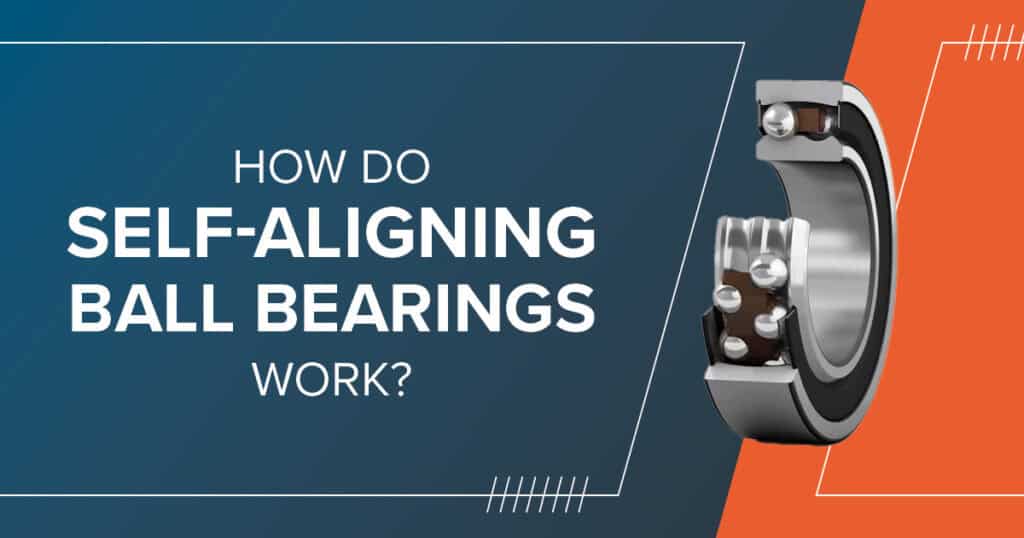

How Do Self-Aligning Ball Bearings Work?

Self-aligning ball bearings can play a pivotal role in the overall performance and durability of industrial pumps and other rotating equipment. Their unique design allows them to manage and adapt to misalignments. They are a valuable component in pump system environments where precision and reliability are critical. The Basics of Self-Aligning Ball Bearings Self-aligning ball […]

A Guide to Internal Gear Pumps

Internal gear pumps are commonly used in a variety of industries because of their efficiency and versatility. This guide will help you gain a better understanding of internal gear pumps. We will talk about how they work and their common applications, as well as their advantages and disadvantages. Is an internal gear pump the right […]

How to Troubleshoot Pump Motor Problems

Facilities and pump equipment are more prone to motor failures the older they become. Motors experience general wear and tear with years of use. Electrical issues or other external factors may lead to equipment damage. Even with an exceptional maintenance and inspection plan, pump motor problems will happen eventually. In some cases, pump motors can […]

Are Diaphragm Seals Right for Your Pump System?

When it comes to choosing the right components for a pump system, one of the crucial decisions involves selecting the appropriate sealing technology. Diaphragm seals are a popular choice for many applications, but are they the right fit for your specific needs? It is important to understand the key considerations, benefits, and potential drawbacks of […]