Selecting the Right Pump for Chemical Processing Applications

Finding the right pump for chemical processing applications is a critical step because of the unique challenges involved in handling various chemicals. These highly specialized applications often require pumps that can withstand harsh environments, prevent contamination, and ensure safe and efficient operation. The proper pump can enhance process reliability, reduce maintenance costs, and improve safety. […]

How to Handle High-Viscosity Fluids

Handling high-viscosity fluids can be challenging for pump operators. These fluids may range from oils and syrups to thick sludges. The viscous nature of these fluids presents unique demands on pumping systems. The higher the viscosity, the thicker and more resistant the fluid is to flow. Understanding how to efficiently pump these fluids is crucial […]

Your Guide to Submersible Pump Sealing Solutions

Submersible pumps operate in challenging environments, often submerged in water or other fluids. This is why reliable sealing solutions are so crucial. Proper seals prevent water ingress to ensure pump longevity and optimal performance. In this article, we will cover the key aspects of submersible pump sealing solutions, including types of seals, common materials, and […]

5 Ways to Optimize Your Predictive Maintenance Plan

Effective pump management is crucial to ensure continuous operation of your pumps. You need to improve equipment efficiency and durability while avoiding unnecessary downtime for maintenance and repairs. Using predictive maintenance technology and optimizing your maintenance plan can mitigate these risks. Here are five key steps you can take to achieve better long-term pump performance: […]

8 Tips for Correcting Pump Shaft Alignment

Proper pump shaft alignment is essential to maintain the performance and longevity of a pump system. Misaligned shafts can lead to excessive wear, increased vibration, and premature equipment failure. This can result in costly repairs and a decrease in operational efficiency. Fortunately, pump shaft misalignment can be properly corrected with the right approach, technology, and […]

Which Pump Coating Is Better: Elastomeric or Ceramic?

Choosing the right pump coating is essential to extend the life of pumps and optimize their performance in demanding environments. Two popular options are elastomeric and ceramic coatings. Each coating has its advantages, which makes them suitable for specific applications based on unique operational challenges. If you are trying to determine which is better for […]

How to Avoid Excess Moisture in Food and Beverage Applications

Excess moisture in food and beverage pumping and packing applications is a common challenge that can lead to various problems. Examples include product spoilage, compromised safety, and reduced operational efficiency of your equipment. One of the most effective tools in managing moisture levels in these environments is a vacuum pump. Vacuum Pumps for Moisture Control […]

Three Important Differences Between Fluids and Liquids

When it comes to pumps, understanding the differences between fluids and liquids is crucial for optimizing performance and efficiency. These terms are often used interchangeably. However, they have very distinct meanings in an engineering context. Specifically, the characteristics of viscosity, density, and vapor pressure are critical to determine how a substance behaves as it flows […]

Custom Solutions for Specific Pump Challenges

At DXP Pacific, we understand every pump system comes with a unique set of challenges. Whether it’s the fluid processing application, a difficult operating environment, or specific performance requirements, no two pump systems are exactly alike. That’s why we pride ourselves on offering custom solutions that address the specific needs of each of our clients. […]

Optimize Your Pump System with a VFD

Pump system optimization is a top priority for all operators. It’s critical to take every step you can to achieve peak equipment performance and longevity. One of the most effective ways to achieve this goal is to integrate variable frequency drives (VFD) into your pump systems. A VFD is an electronic device that varies the […]

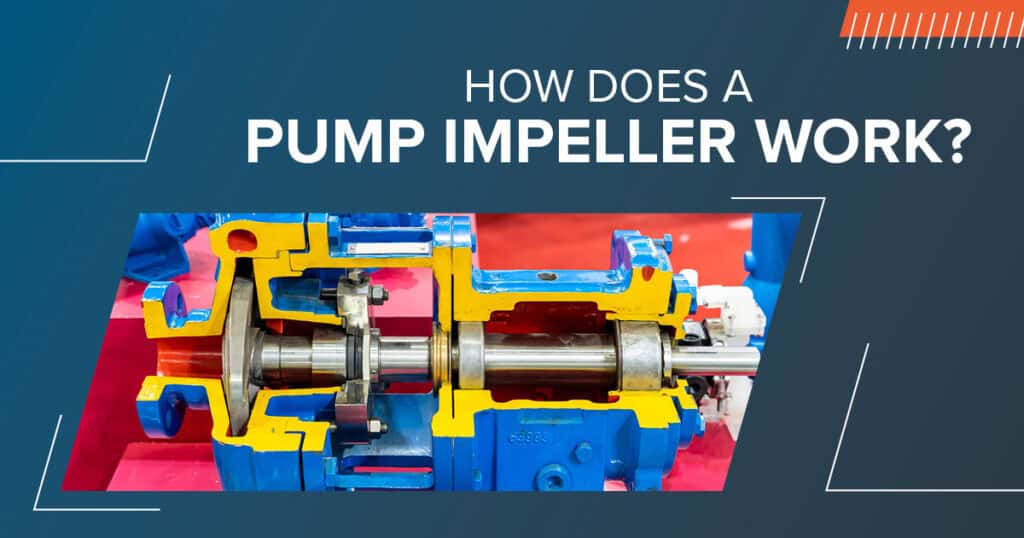

How Does a Pump Impeller Work?

The impeller is a critical component in centrifugal pumps. It is responsible for the efficient movement of fluid through the pump system. As an operator, it is beneficial to understand how the impeller works. In this article, we will explore the impeller’s design, operational principles, and the different types of impellers available. Impeller Basics The […]

Pump Troubleshooting: How to Identify a Seal Leak Source

One of the most common mechanical problems that can arise with pumps is a seal leak. Identifying the source of a seal leak is crucial for maintaining the efficiency and longevity of your industrial or municipal pump system. Experienced operators and engineers know the following steps can be taken to effectively troubleshoot a pump seal […]