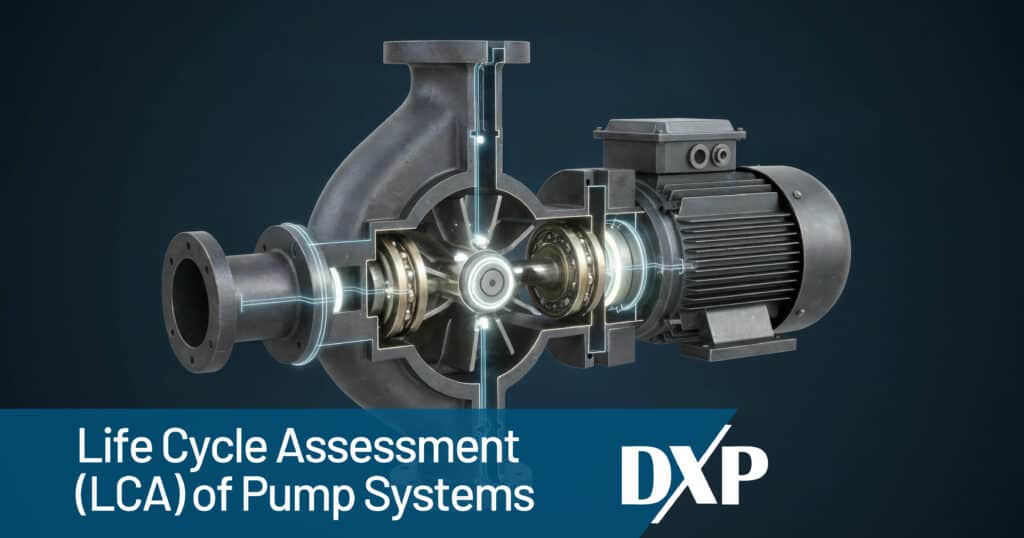

Life Cycle Assessment (LCA) of Pump Systems

Selecting a pump involves more than comparing upfront purchase prices. The true cost and environmental footprint of a pump extend across its entire operational life—from raw material extraction and manufacturing to daily energy use and end-of-life disposal. Life Cycle Assessment (LCA) is a structured approach that evaluates these impacts over time, offering valuable insight into […]

Deploying Intelligent Pumps for Automation

In today’s industrial landscape, automation is critical to staying competitive. Smart technologies have transformed many facets of manufacturing and processing operations, and pumps are no exception. Intelligent pumps equipped with adaptive controls are reshaping the way facilities manage fluid movement, energy consumption and maintenance planning. By deploying these advanced systems, companies can reduce operational costs, […]

The Importance of Right-Sizing Pumps

Selecting the right pump is one of the most critical decisions in any fluid handling system. A pump that’s too large or too small for the job can waste energy, reduce performance and shorten the life of both the pump and associated equipment. Right-sizing ensures that your pump matches the specific needs of the application, […]

Integrating IoT Sensors in Pump Monitoring

In today’s data-driven landscape, real-time insight is everything. For pump systems, the integration of IoT (Internet of Things) sensors is revolutionizing the way operators monitor, maintain and optimize performance. These sensors transmit continuous operational data, which can significantly reduce downtime, improve reliability and extend the lifespan of critical pump assets when monitored properly. The Evolution […]

Critical Benefits of Routine Pump Lubrication

Lubrication is one of the simplest yet most essential practices in pump maintenance. Whether your facility operates centrifugal, positive displacement or submersible pumps, routine lubrication plays a critical role in ensuring long-term reliability and efficiency. Without it, pumps are far more likely to suffer from premature wear, overheating and unexpected downtime. By establishing a consistent […]

Enhancing Energy Efficiency in Pump Systems

While pumps are essential for moving fluids reliably, they are also one of the largest consumers of industrial energy. In fact, studies estimate that pumping systems account for nearly 20–25% of the world’s total industrial electricity use. The good news is that significant opportunities exist to improve pump energy efficiency, cutting costs and reducing environmental […]

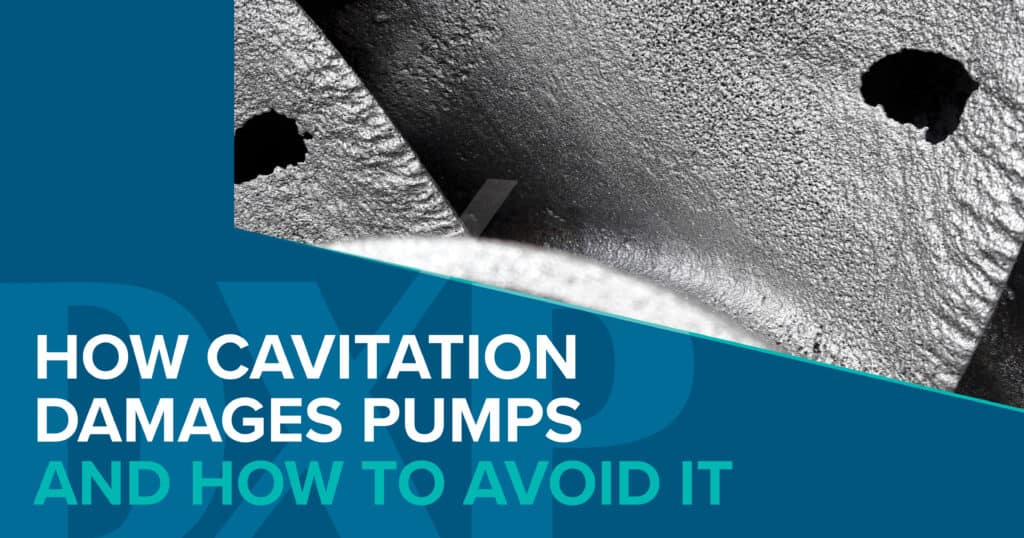

How Cavitation Damages Pumps and How to Avoid It

Cavitation is one of the most common and destructive problems in pump systems. Left unchecked, it can quickly erode critical components, reduce efficiency and shorten equipment lifespan. Understanding how cavitation occurs, recognizing the warning signs and implementing the right countermeasures are essential for protecting your pumps and maintaining reliable operations. What Is Cavitation? Cavitation occurs […]

7 Maintenance Strategies for Submersible Pumps

Submersible pumps are indispensable in industries ranging from municipal water and wastewater treatment to mining, construction and food processing. Designed to operate while fully submerged, these pumps face unique stresses that above-ground equipment does not. They deal with constant exposure to water, abrasive particles, corrosive fluids and challenging operating environments. Without the right maintenance strategies, […]

How Thermodynamic Testing Can Boost Pump Accuracy

When it comes to industrial pump performance, small inefficiencies can quickly turn into big operational headaches. Energy waste, reduced flow rates and unexpected downtime all stem from inaccurate performance measurements. Thermodynamic testing is one of the most reliable methods for pinpointing how well a pump is operating and ensuring systems are running at peak efficiency. […]

6 Signs Your Pump Needs an Upgrade

Industrial pumps are built for longevity, but even the most robust systems eventually show signs of aging, wear, or inefficiency. Waiting until your pump completely fails can lead to unplanned downtime, costly repairs, and production delays. The key to avoiding these consequences is knowing the early warning signs that your pump needs to be replaced […]

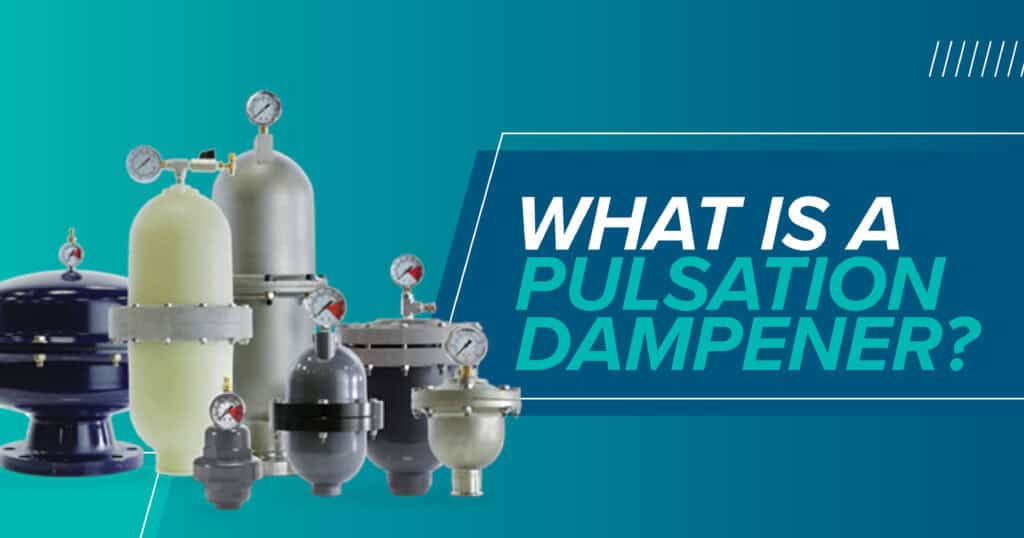

What is a Pulsation Dampener?

Understanding the Role of Pulsation Dampeners in Pump Systems In fluid handling systems, pressure fluctuations are a common challenge—specially those using positive displacement pumps. These pulsations can lead to equipment wear, inaccurate instrumentation readings and inefficient system performance. One of the most effective solutions to this problem is the installation of a pulsation dampener. The […]

The Future of Industrial Pumps: Emerging Technologies to Watch

Industrial pumps play a vital role across multiple sectors—from municipal water treatment and oil and gas to pharmaceuticals and food processing. As industries face increasing pressure to improve efficiency, reduce carbon footprints, and use real-time data, the pump sector is experiencing a wave of transformative technological innovation. Here’s a closer look at key emerging trends […]