Cortech offers many different types of pumps, and one of the most common types of pump purchased is a centrifugal pump. Centrifugal pumps work best for specific types of applications, and it is important to understand how these pumps work to best determine if a centrifugal pump is what is needed for your particular application.

SEE ALSO: What is a Submersible Pump?

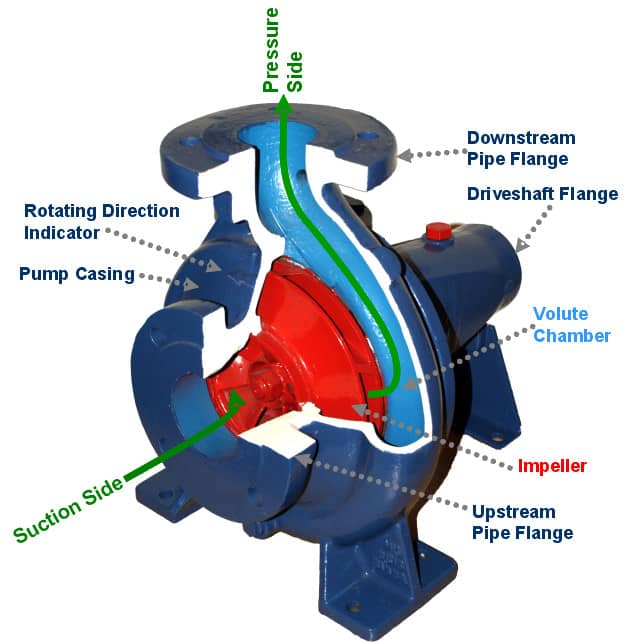

In essence, a centrifugal pump works by converting rotational energy into energy in a moving fluid. Most centrifugal pumps consist of an impeller, the casing, and a motor. There are other parts required, as well, but these are the main components. The impeller is the part that spins in a circular rotation and is submerged in water. The rotational energy in the impeller often comes from a motor. The energy expended by the impeller causes the water to rotate in the same direction as the impeller forcing the water to gain velocity and pressure. This energy is coming directly from the impeller. Surrounding the impeller is the casing. The casing increases the surface area of the impeller which helps to increase the pressure of the surrounding water. This allows the water to flow more freely through a part called the diffuser. When passing through the diffuser, the water’s velocity will decrease causing the pressure to increase once again. The amount of pressure now contained in the water is finally released when it exits out the opposite end of the pump, thus completing the movement of the water from the front of the pump to the back.

Centrifugal pumps are most commonly used in the oil industry but can be used in many other industries, as well. Cortech is proud to offer a wide variety of centrifugal pumps from the most trusted and respected pump companies in the business today. Our knowledgeable staff can assist you in determining the best centrifugal pump for your application. Give them us call today to speak with a pump expert.