4 Tips to Optimize Your Existing Pump System

Ultimately, your goal is to have a full optimized pump system. You want it working as efficiently as possible to save on energy costs. You want it to be reliable to minimize downtime, lost production, and repair expenses. If your pump isn’t fully optimized, you are wasting time and money. It’s as simple as that. […]

Transfer High-Viscosity Fluids with a Circor Screw Pump

Circor is a leading manufacturer of motion and flow control solutions to handle the most demanding applications. They represent pumps and products from a wide list of brand subsidiaries, including many different types of pumps depending on your needs. Circor Screw Pump Brands Circor offers an exceptional line of screw pumps from quality brand names […]

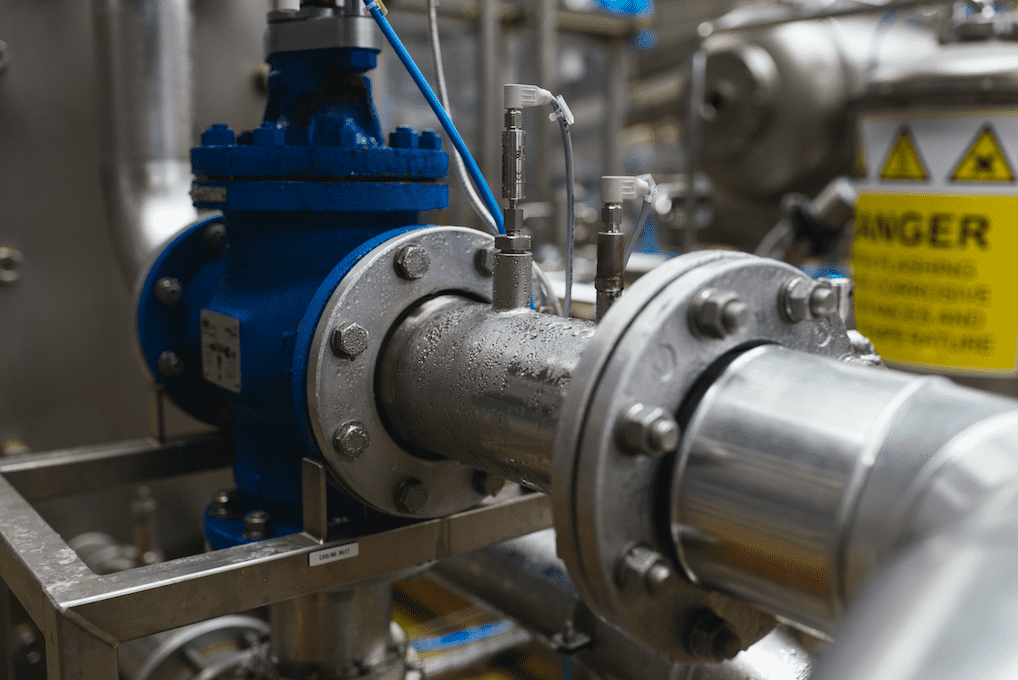

What is NPSH and Why is it So Important to Pump Performance?

Net positive suction head (NPSH) is an important measure used by centrifugal pump engineers and pump operators. It is a matter of the pressure energy within a liquid that enables the fluid to be fed into the eye of the first-stage impeller. How to Calculate NPSH NPSH is calculated by adding the total static and […]

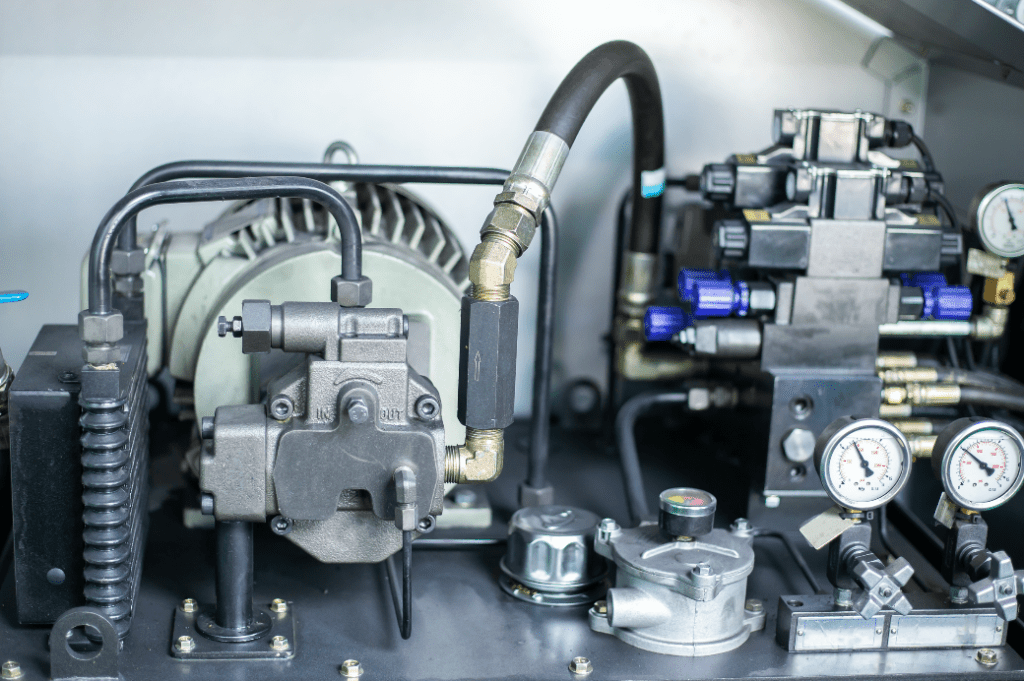

5 Applications Ideal for Metering Pumps

Metering pumps are designed to handle a wide range of different chemicals and fluids, including acids, bases, corrosives, and highly viscous liquids. The primary advantage of metering pumps is their ability to provide highly precise control over flow rate and capacity, typically within one-half of one percent (0.5%) accuracy. Different types of metering pumps exist […]

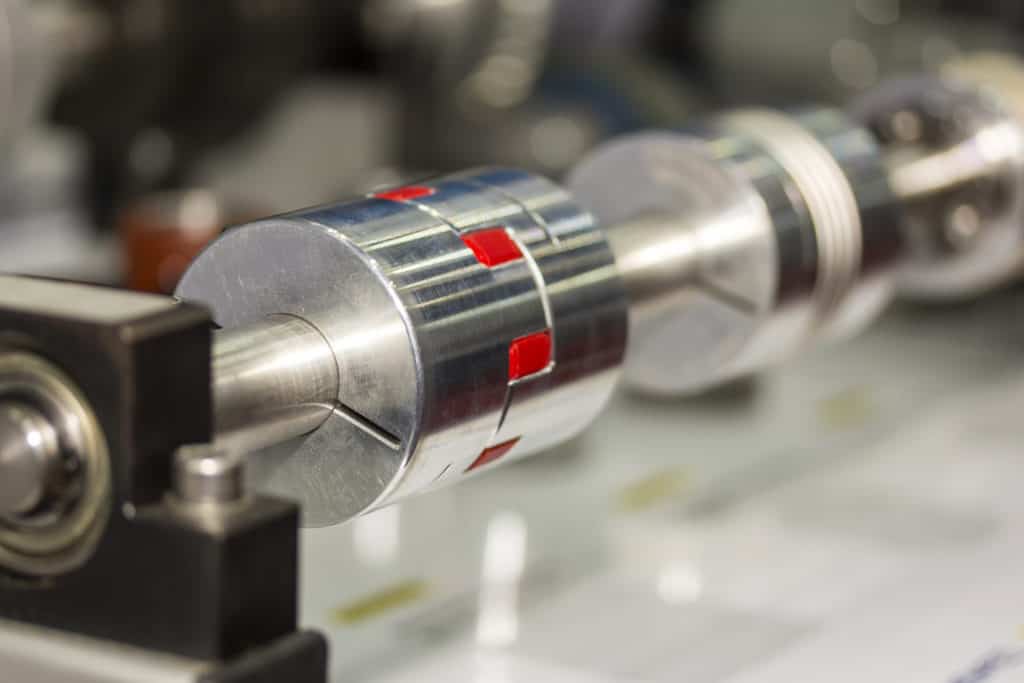

Six Tips for Setting Pump Bases to Achieve Proper Leveling

When you need the best performance and longevity from a pump, installation on a level surface is critical. Each pump component must be aligned carefully to achieve the desired results over the life of the pump. Pumps set at improper levels are a common problem we see when out in the field repairing pumps installed […]

Why a Gear Pump is Best for Viscous Materials

Oil and other high-viscosity liquids can present a unique challenge for many pumps. Operators who regularly deal with viscous materials prefer gear pump systems because they handle difficult fluids more efficiently and effectively. Gear pumps are often found in applications like oil and gas, industrial, mining and aggregate, water and wastewater treatment, municipal, and food […]

The Benefits of an Air-Operated Double-Diaphragm Pump (AODD)

The Air-Operated Double-Diaphragm Pump (AODD) is a type of positive displacement pump that many operators prefer over standard centrifugal pumps for certain thick and viscous fluid applications. AODDs are commonly used in industries like food processing, electronics, pharmaceuticals, paints and oil, acid transfer metering, and gas. Four key benefits of Air-Operated Double-Diaphragm pumps: Simple […]

Increase Volumetric Efficiency with Blackmer Rotary Vane Pumps

Blackmer, the world’s premier manufacturer of rotary vane pumps, has been in operation since 1903. Today, the Blackmer name is synonymous with energy efficiency, dependability and reduced maintenance costs. Applications include petroleum and liquefied gas, viscous liquids, volatile organic compounds and industrial process fluids. Industries ranging from commercial manufacturing to U.S. defense agencies have relied […]

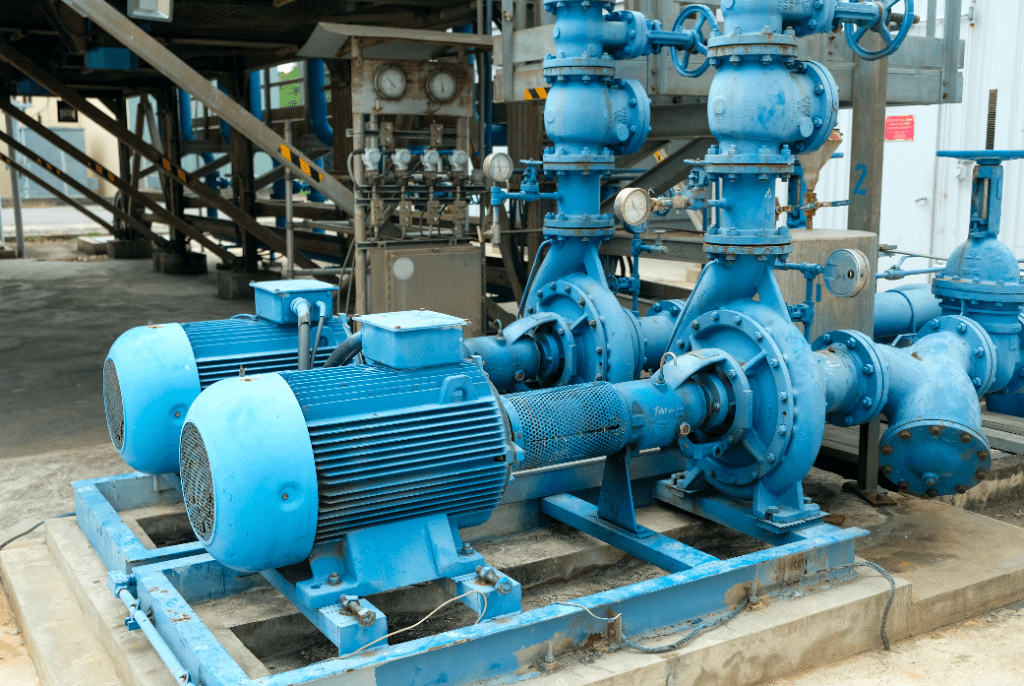

The Differences Between Horizontal and Vertical Centrifugal Pumps

Centrifugal pumps are found in many industrial applications. They provide excellent operational efficiency and versatility when it comes to pressures and liquid flows. Inline centrifugal pumps will come in to distinct configurations: horizontal and vertical. What are the differences between the two inline styles of centrifugal pumps? And, which one is right for your […]

Gain Reliability and Efficiency with the PumpWorks HP Plus Pump

PumpWorks has been a leading specialty manufacturer of API 610 and ANSI process pumps for decades. Their company’s roots date back to 1978. Their products and services have been evolving ever since, which is why it’s easy to understand why so many industries turn to them for exceptional pump equipment. The PumpWorks HP Plus […]

4 Drivers of Pump Bearing Longevity

Proactive maintenance is so important when it comes to minimizing downtime and extending the lifespan of your pump equipment. One of the most common sources of pump problems is the pump bearing. If the bearing assembly is damaged, deteriorated or not operating properly, it will lead to excessive heat and vibration. This leads to equipment […]

Why Use a Self-Priming Pump?

Self-priming pumps offer certain advantages over standard centrifugal pumps that require manual priming. The biggest difference is obviously that they prime themselves without the need for outside attention. Not only does this make self-priming pumps more efficient than alternative designs, it also provides additional benefits that are useful in many industrial applications. How Self-Priming […]