Use Data to Dial in Your Pump Maintenance

Pump operators are extending the lives of their equipment and lowering costs using predictive maintenance techniques. Also known as data-driven pump maintenance, the approach uses computer monitoring to gather data about pumps in a system and bases maintenance schedules around the gathered data. Rather than relying on assumptions, operators using predictive maintenance can schedule work […]

5 Ways to Minimize Pump Downtime

Every pump system will require some downtime for general maintenance, replacing parts and making repairs. It’s inevitable you will have to shut the equipment down from time to time. The key is to minimize how much downtime is required. This will increase uptime with a more efficient and productive pump system. So, how do you […]

How to Identify Sources of Pump Failure

It takes a very experienced pump operator to effectively troubleshoot and identify potential sources of pump system failures. It’s not an easy task. However, there are some consistent steps to help decipher the problem and address it with necessary maintenance or repairs. Recognition of Pump Failure The first questions to ask are when and how […]

Sanitary Pump Maintenance: The Steps You Need to Take

There are numerous applications that require sanitary pumps to meet specific hygienic standards. They are commonly used in industries such as food and beverage, chemical processing, dairy, pharmaceuticals, brewing, and distilling. Each application may call for specific hygienic pump specifications. A well-maintained sanitary pump should provide reliable performance for many years. Maintenance can be minimal […]

6 Ways to Keep Your Pump Motor Healthy

All pumps operate using some sort of motor drive system. There are actually many different ways to produce pumping power, depending on the type of pump and the operating environment. The most common are fuel-driven or electric motors. All pump motors require monitoring and maintenance to perform their best and last longer. Let’s review some […]

Improve Pump Safety and Efficiency with Preventative Maintenance

Maintenance is critical when operating any type of equipment. You get the oil changed in your car or truck and you replace worn parts like brake pads and tires. Why wouldn’t you apply the same care to your pump systems and other industrial machinery? You depend on your pump every day. The proper preventative maintenance […]

5 Tips for Pumping Corrosive Liquids

Pumping corrosive liquids, abrasive materials, hazardous fluids, and harsh chemicals presents many challenges. Corrosive liquids degrade, damage, and even destroy specific pump system components. In addition, certain metals, plastics, and glass can experience significant corrosion when pumping these fluids and chemicals. There are several concerns when it comes to pumping corrosive liquids. First, your equipment […]

Your Guide to Pump Lubrication

Pump systems transport various materials, from water and chemicals to slurries and solids. Many different types of pumps use different mechanical processes to create suction and push liquids through the pump. For example, you have centrifugal pumps, diaphragm pumps, screw pumps, progressive cavity pumps, and many others. Each pump and system type will require specific […]

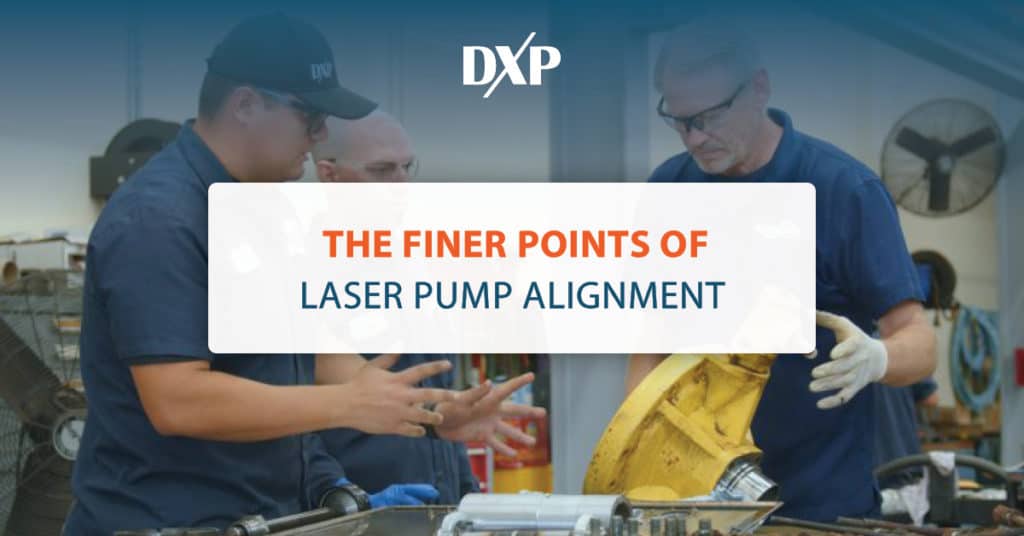

The Finer Points of Laser Pump Alignment

You can achieve optimal pump alignment—technology, technique, and laser alignment being paths to get you there. Keep reading to learn from DXP Pacific’s strategies. Technology and Technique At DXP Pacific, we often utilize old-school manual pump alignment techniques in addition to high-tech solutions like laser pump alignment. Lasers offer unprecedented accuracy and speed, but […]

7 Easy Tips for Better Pump Maintenance

If you want to keep your pump system running at optimum performance and efficiency, you need to perform maintenance. Maintenance entails equipment inspections, testing, minor repairs, settings adjustments, cleaning and replacing worn seals, hoses, bearings, and other standard part audits. We consider this “preventative maintenance,” as it prevents considerable damage and breakdowns that will cost […]

When are On-Site or In-House Pump Repairs the Best Fit?

DXP Pacific goes beyond pump equipment supplies—we provide professional pump system design, installation, maintenance, training, and repair services as well. In addition, your preventative maintenance program will be completely tailored to your needs. To your equipment running optimally, consider whether on-site or in-house pump repairs are the better fit. Pump Repair Services What happens when […]

What is Soft Foot and Why is it So Important to Leveling Pump Bases?

Soft foot is a common problem often seen in pumps and rotating machines that need to be set on permanent bases. Such equipment must be perfectly level with all components precisely aligned for ideal performance. If anything is out of alignment or not securely in place, pump problems, and even damage, are a near certainty. […]