The Finer Points of Laser Pump Alignment

You can achieve optimal pump alignment—technology, technique, and laser alignment being paths to get you there. Keep reading to learn from DXP Pacific’s strategies. Technology and Technique At DXP Pacific, we often utilize old-school manual pump alignment techniques in addition to high-tech solutions like laser pump alignment. Lasers offer unprecedented accuracy and speed, but […]

Best Applications for an AODD Pump

Air-operated double-diaphragm pumps (better known as AODD pumps) are growing in popularity throughout various industries and applications. Their unique design and gentle movement make them ideal for handling challenging media, including shear-sensitive solids, slurries, corrosive chemicals, and highly viscous fluids. There are many different ways to utilize AODD pumps effectively. Air-operated double-diaphragm pumps are positive […]

How Custom Pump System Design Can Save You Money Over Time

Considering the total cost of ownership (TCO) will help you select the best pump system for your operation—but what goes into this total cost? • Equipment Purchase • Customizations • Installation • Maintenance • Parts Replacement • Repairs • Energy/Fuel Consumption • Productivity Gains and Losses (Processing […]

How to Select the Best Progressive Cavity Pump

Progressive cavity pumps are effective for certain applications and fluids. However, they are not ideal for every application, which is something that can generally be said for most different types of pumps. Proper pump selection is always critical. You have to find, configure and operate the right pump system to produce the optimum results for […]

Key Pump Challenges to Overcome in Extreme Operating Conditions

Some pump applications present more challenges than others. The environment around your pump system can have extreme temperatures, humidity, or weather patterns, while the processing fluids are hazardous, corrosive, and abrasive. There’s no shortage of applications with unique operating conditions that require proper pump selection, system design, installation, monitoring, and maintenance. Here are 6 of […]

Metering Pumps for Power Generation

Power plants worldwide can turn common water into consumable energy. These plants have complex systems that pull water from rivers, lakes, and aquifers by utilizing a series of pumps, clarifiers, and filters. Some of the pumped water is converted into steam energy through specific processes, while a vast majority of water is used for cooling […]

What is a Wobble Pump and in Which Applications is it Best Suited?

A wobble plate piston pump (more commonly referred to simply as a “wobble pump”) is a specialty pump ideal for applications that require a great deal of pressure. Some wobble pumps can handle up to 10,000 PSI or more, making it ideal for high-pressure, low-volume applications. How it Works A wobble pump works by using […]

5 Applications Ideal for Metering Pumps

Metering pumps are designed to handle a wide range of different chemicals and fluids, including acids, bases, corrosives, and highly viscous liquids. The primary advantage of metering pumps is their ability to provide highly precise control over flow rate and capacity, typically within one-half of one percent (0.5%) accuracy. Different types of metering pumps exist […]

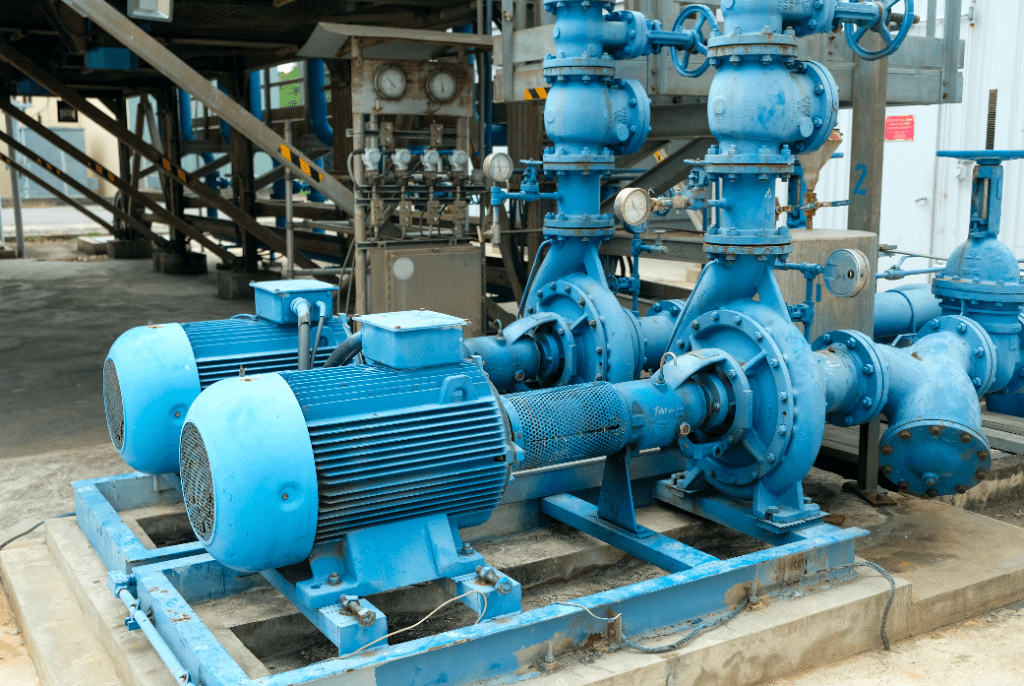

What is Soft Foot and Why is it So Important to Leveling Pump Bases?

Soft foot is a common problem often seen in pumps and rotating machines that need to be set on permanent bases. Such equipment must be perfectly level with all components precisely aligned for ideal performance. If anything is out of alignment or not securely in place, pump problems, and even damage, are a near certainty. […]

9 Tips for Reducing Pump Ownership and Operation Expenses

No matter the industry you’re in, you have to watch your bottom line. Expenses add up and eat into profits, but as a plant operator you also need to make sure the jobs get done right. It’s a fine line to walk when it comes to owning, operating, and maintaining heavy-duty pumps. There’s energy consumption, […]

How Machine Grouting will Give Your Pump the Strongest Foundation

Properly mounting a pump is a necessity that is often overlooked or undervalued by plant operators. Unfortunately, it’s something we see far too often. Someone will buy the least expensive baseplate that’s available and place it on the floor with less-than-ideal footing and alignment. Before long, the pump is damaged or requires maintenance because bearings, […]

Six Tips for Setting Pump Bases to Achieve Proper Leveling

When you need the best performance and longevity from a pump, installation on a level surface is critical. Each pump component must be aligned carefully to achieve the desired results over the life of the pump. Pumps set at improper levels are a common problem we see when out in the field repairing pumps installed […]