4 Drivers of Pump Bearing Longevity

Proactive maintenance is so important when it comes to minimizing downtime and extending the lifespan of your pump equipment. One of the most common sources of pump problems is the pump bearing. If the bearing assembly is damaged, deteriorated or not operating properly, it will lead to excessive heat and vibration. This leads to equipment […]

Why Use a Self-Priming Pump?

Self-priming pumps offer certain advantages over standard centrifugal pumps that require manual priming. The biggest difference is obviously that they prime themselves without the need for outside attention. Not only does this make self-priming pumps more efficient than alternative designs, it also provides additional benefits that are useful in many industrial applications. How Self-Priming […]

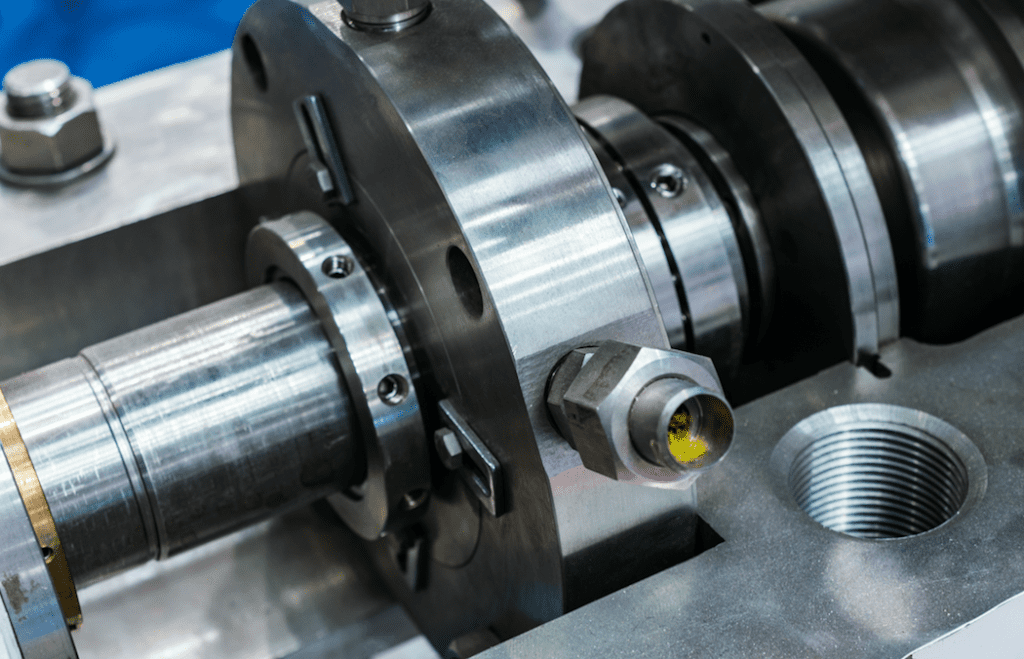

Milton Roy Metering Pumps Deliver Accurate Results

The most important function of a metering pump is to provide accuracy and consistency during operation. You want the process fluid to be transported at controlled flow rates and with optimum energy efficiency. Milton Roy (MilRoy) metering pumps deliver the accurate results you desire, with exceptional precision and performance. Every gear in a Milton […]

Pitbull Pumps Show the Advantages of Simple Design

You don’t have to have an overcomplicated design to have a quality pump. The core physics of pumping have not changed. Yet, many pump designs have evolved to have so many complex features, especially when it comes to handling solids and debris in wastewater and slurry applications. Some of these features are nice, but are […]

Verderflex Peristaltic Pumps Offer Robust Solutions

Verderflex is a leading manufacturer of peristaltic pumps, which are a specialized type of pump used in a wide variety of industries. Peristaltic pumps work using alternating compression and relaxation of a hose or tube. The hose draws contents in, then a rotating shoe rolls along the length of the hose. This provides compression […]

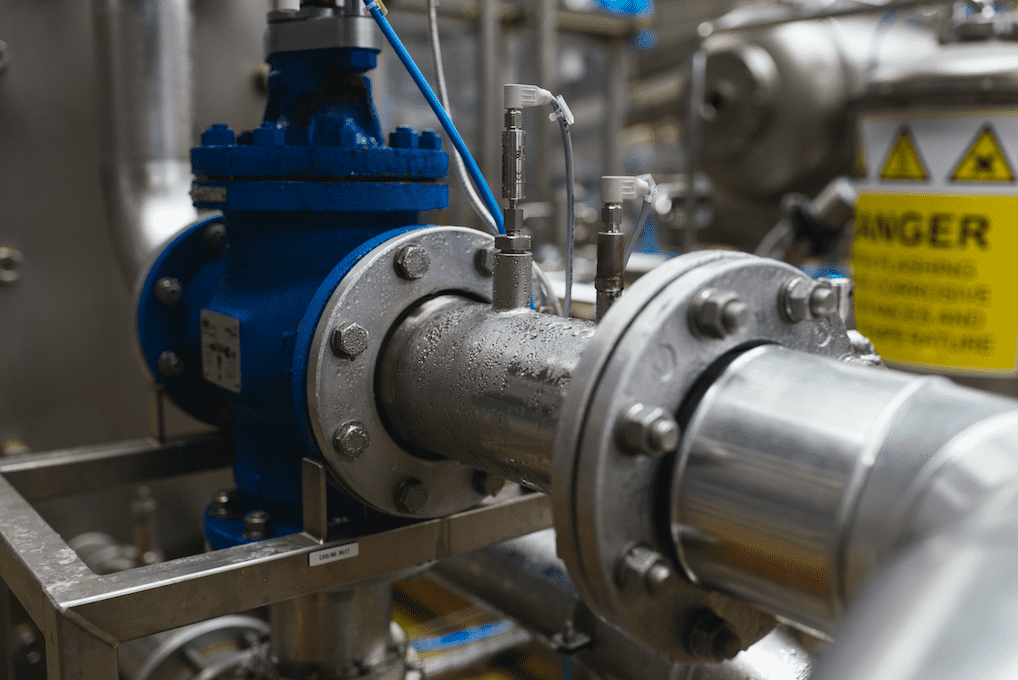

Preparing Pumps for Cold Weather Conditions

Winter is already in full swing and you probably already notice that operating your pumps is more challenging when the weather is colder. The colder it gets, the more difficult it is to run and maintain pumps efficiently, especially if you are pumping remote locations. Slurry pumps are known to struggle the most during […]

How a Slurry Pump Handles the Rough Stuff

Any operator who has ever pumped slurry will tell you how difficult a job it can be. It is one of the most challenging fluids to process because it involves a lot of extra variables. Slurries can contain a high amount of solids and will typically have a much thicker consistency than normal fluids. They […]

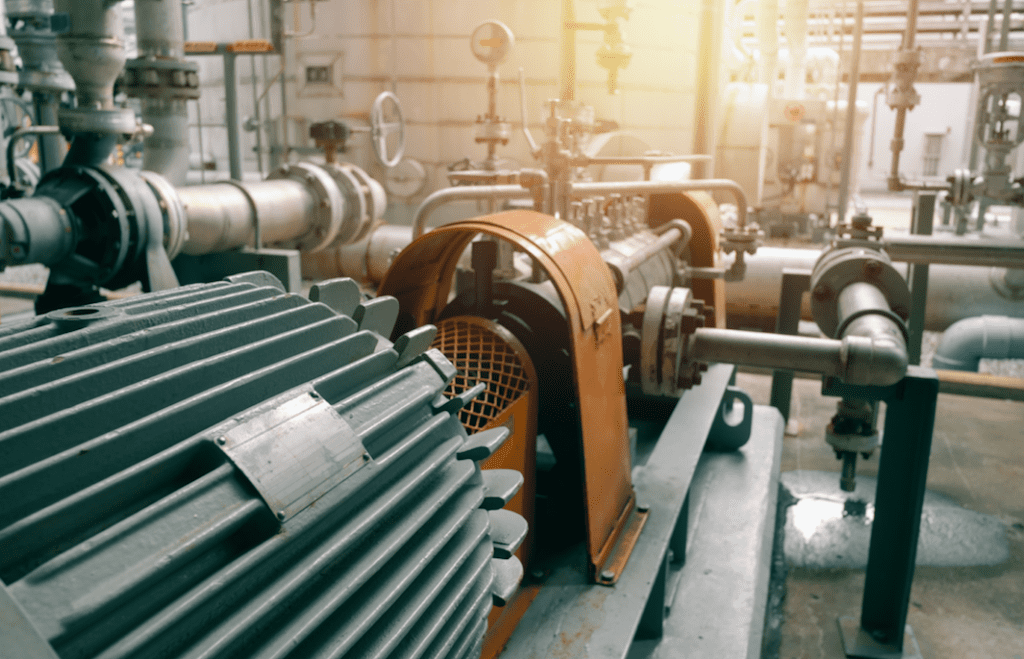

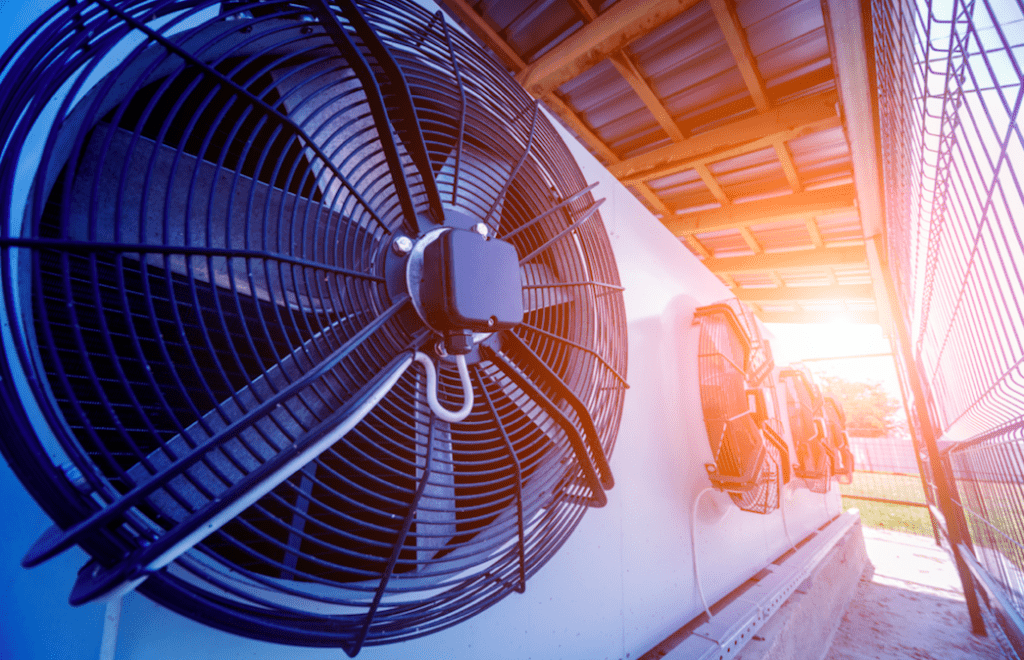

How Variable Speed Compressors Are Changing the Industry

Almost every manufacturing facility will have compressed air or refrigeration systems as a major part of the plant. These systems can use up to 30% of the facility’s energy consumption. Traditional screw compressors can be major consumers of energy. Their starting and stopping cycles typically aren’t very efficient, the mechanical components can wear out and […]

Tackling Tough Jobs with Cornell Slurry Pumps

Processing slurries and fluids containing solid materials can be tough work. These are among the most demanding applications in the pumping industry. Milling, mining, manure slurries, wastewater and abrasive chemicals present many challenges. You need a slurry pump that can handle the job with reliable performance and extended durability. Cornell is a leading pump […]

SEEPEX Metering Pumps Deliver Precision

When you have viscous media, media containing solids and/or chemically corrosive media, you need a pump that can provide low pulsation and perform at consistently precise flow rates. Ideally, you want something that works dependably—down to the exact drop! SEEPEX offers its incredible D line of metering pumps to achieve this kind of precision, […]

Achieving Efficiency in High-Pressure Pumping

High-pressure pumping applications such as chemical, petrochemical, pipeline transfer service, water injection and polyethylene terephthalic acid (PTA) reactor feeds need an API-compliant centrifugal pump that can handle flow rates of 300-1,500 gallons per minute (gpm) and heads up to 15,000 feet (4,572 meters). Why You Need Peak Efficiency In these high-pressure applications, reliable performance […]

A Closer Look at PumpWorks ANSI Process Pumps

ANSI process pumps are a specific type of end-suction centrifugal pump with a single-stage design. They are used primarily in chemical processing, and can also be found in refineries, ethanol production, paper mills and various other industries. They are designed to meet strict ASME B73.1 standards. Although every pump built to meet ASME standards have […]