5 Steps for Troubleshooting Centrifugal Pump Problems

Problems with a centrifugal pump can be frustrating. Issues can cause equipment damage or lead to costly downtime for unplanned repairs. One of the best ways to avoid these complications is to have a consistent preventative maintenance plan. However, unexpected problems can always happen without much warning. You must be ready to troubleshoot and resolve […]

3 Ways to Repair Pump Corrosion Damage

Corrosion and erosion are unavoidable in many pump applications. Even the most protected operating environments can bring external factors that corrode parts, develop rust, or cause natural erosion to welds and key connection points. Corrosion can also happen from the inside when dealing with harsh process materials. This wear and tear can ultimately lead to […]

5 Ways to Minimize Pump Downtime

Every pump system will require some downtime for general maintenance, replacing parts and making repairs. It’s inevitable you will have to shut the equipment down from time to time. The key is to minimize how much downtime is required. This will increase uptime with a more efficient and productive pump system. So, how do you […]

How to Identify Sources of Pump Failure

It takes a very experienced pump operator to effectively troubleshoot and identify potential sources of pump system failures. It’s not an easy task. However, there are some consistent steps to help decipher the problem and address it with necessary maintenance or repairs. Recognition of Pump Failure The first questions to ask are when and how […]

Advantages & Disadvantages of a Vacuum Pump

Are you trying to decide between a diaphragm pump and a vacuum pump? If so, there are several issues you will need to consider. Vacuum pumps are great for certain applications, but not ideal for others. A diaphragm pump or some other sort of positive displacement pump might be a better solution. How Does a […]

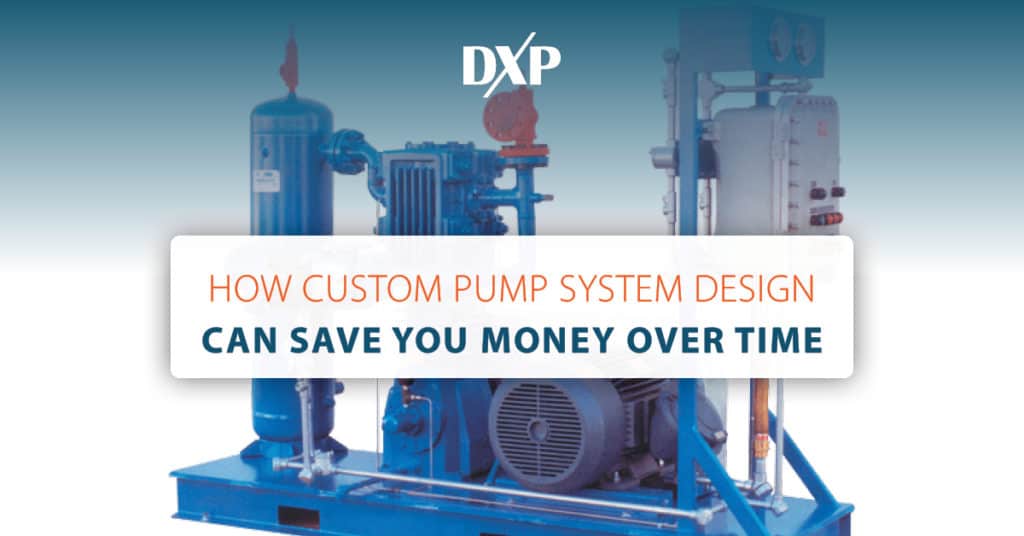

How Custom Pump System Design Can Save You Money Over Time

Considering the total cost of ownership (TCO) will help you select the best pump system for your operation—but what goes into this total cost? • Equipment Purchase • Customizations • Installation • Maintenance • Parts Replacement • Repairs • Energy/Fuel Consumption • Productivity Gains and Losses (Processing […]

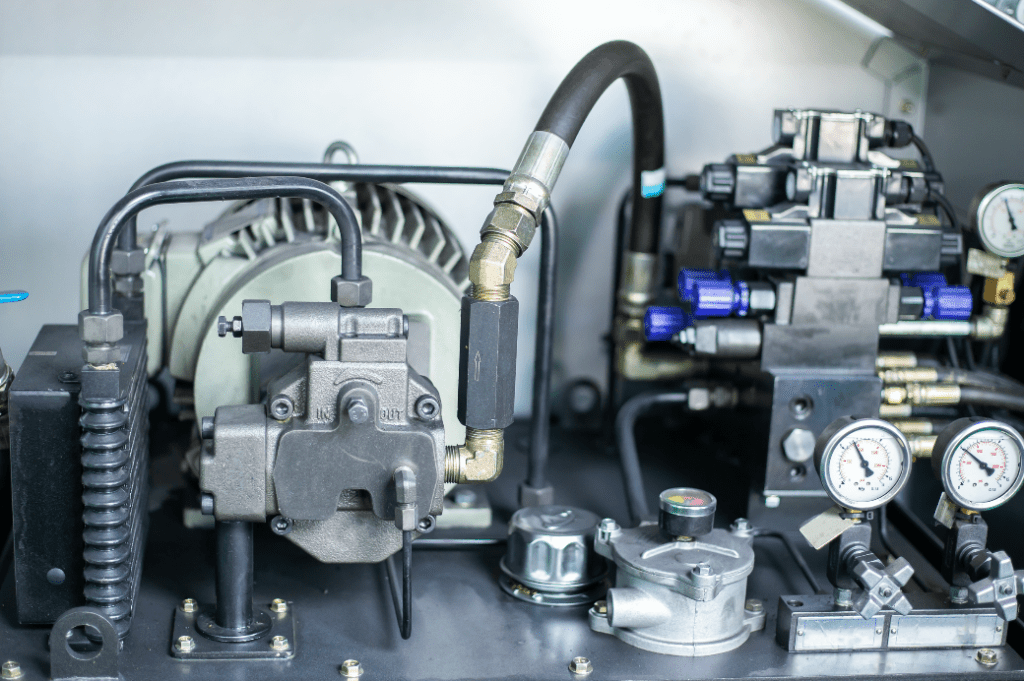

When are On-Site or In-House Pump Repairs the Best Fit?

DXP Pacific goes beyond pump equipment supplies—we provide professional pump system design, installation, maintenance, training, and repair services as well. In addition, your preventative maintenance program will be completely tailored to your needs. To your equipment running optimally, consider whether on-site or in-house pump repairs are the better fit. Pump Repair Services What happens when […]

Why a Gear Pump is Best for Viscous Materials

Oil and other high-viscosity liquids can present a unique challenge for many pumps. Operators who regularly deal with viscous materials prefer gear pump systems because they handle difficult fluids more efficiently and effectively. Gear pumps are often found in applications like oil and gas, industrial, mining and aggregate, water and wastewater treatment, municipal, and food […]

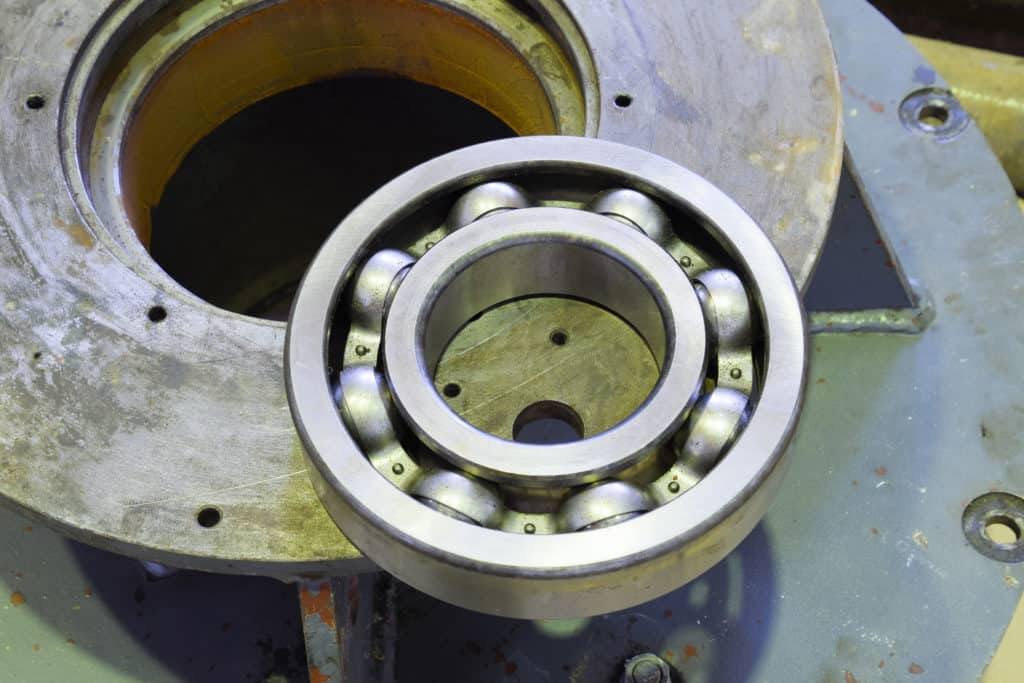

What Effects Does Internal Clearance Have on Bearing Life?

When it comes to maintaining a bearing and maximizing its lifespan, internal clearance is an important factor to understand. If the clearance isn’t right, bearings will not perform efficiently and they will wear out more quickly. What is Internal Clearance? First, it pays to understand what internal clearance represents. In essence, it is the […]

How to Handle Cavitation in Your Application

Cavitation is a serious concern for pump operators. It occurs when miscalibration or other problems cause the formation and subsequent implosion of vapor bubbles within a pump. Cavitation can happen anywhere the pressure of a process liquid falls below it’s ideal vapor pressure. Why is Cavitation a Problem? When cavitation occurs, it can do […]

How to Prevent Valve Noise and Flow Damage

Most pump operators and piping system managers are most concerned about leaks and maintaining the desired flow rate. However, two other major issues are valve noise and damage from choked flow or cavitation. Our team at Cortech Engineering has put together a couple of tips you can incorporate into your operation that will help prevent […]

How BJM Shredder Pumps Help to Avoid Pump Repair and Submersible Pump Failure

Pump failure is a common problem at wastewater facilities. Non-biodegradable solids buildup can bring an operation to a grinding halt. The submersible pump will clog and ultimately fail, leading to increased downtime for repairs and maintenance. The good news is there are ways to manage the challenges presented by solids buildup in wastewater operations. Here […]