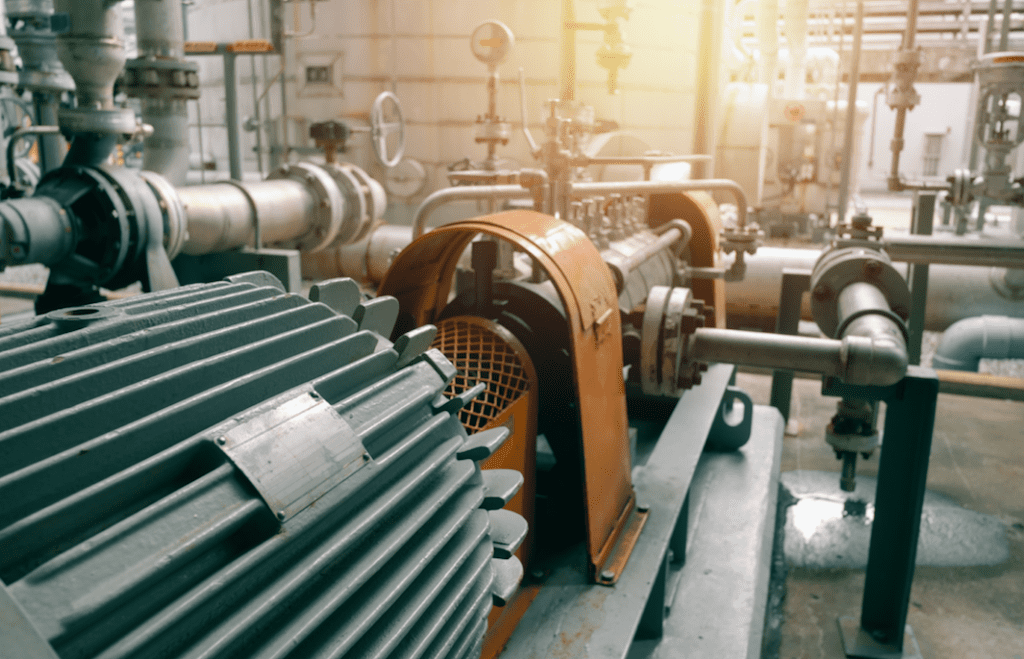

Are You Losing Money from Inefficient Pump Motor Management?

Most pumps and other types of rotating equipment run on electricity. If that’s the case at your facility, the odds are good your motors account for a large portion of your electric bill each month. This is why efficient pump motor management is so critical. You could be throwing money out the window every day. […]

6 Reasons to Practice Remote Pump Monitoring

Remote pump system monitoring is becoming more common for many reasons. It can reduce labor costs in a time when great operators are hard to find. It can improve equipment performance and reduce operating costs. It can completely streamline your maintenance plan through predictive data. What is Remote Pump Monitoring? Remote pump monitoring is a […]

5 Tips for Optimizing Boiler Feed Pumps

Thermal power plants rely on boiler feedwater pumps. Water is pumped into the boiler at high pressures to generate steam. Unfortunately, boiler feed pumps often consume a lot of energy. It is critical to optimize your equipment to reduce operating costs and improve the power plant’s overall thermal efficiency. Even the smallest increase in energy […]

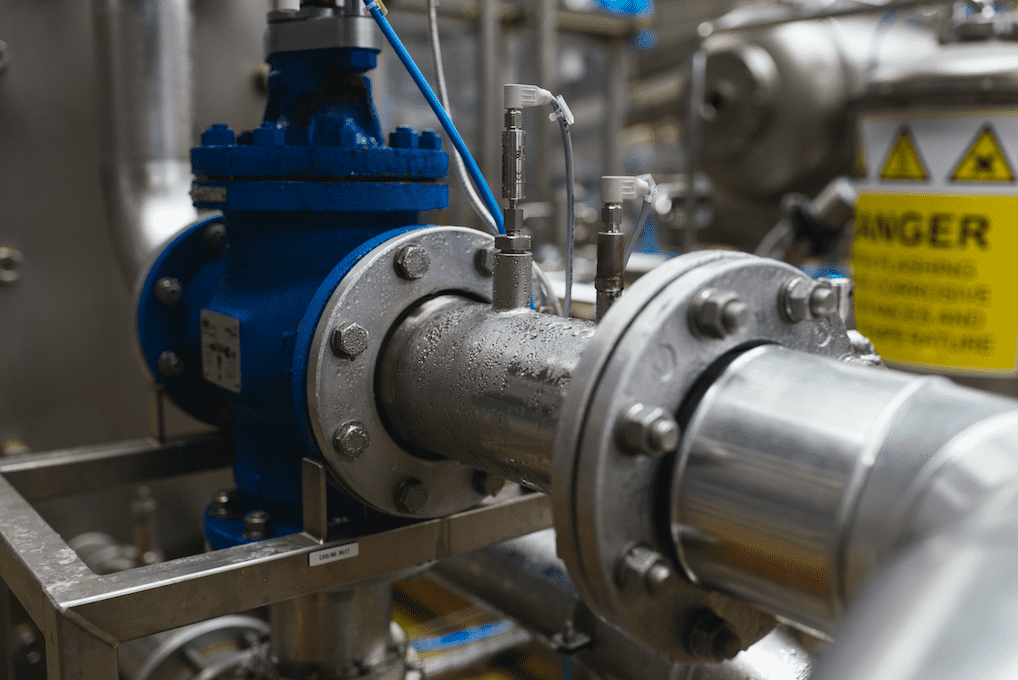

Improve Water Quality with the Right Mechanical Seal

Mechanical seals are crucial components in water treatment pump systems. They minimize the risk of costly pump leaks, which can lead to lost water, lost pump pressure, reduced energy efficiency and damaged equipment. Most importantly for this application, they prevent outside contaminants from entering the water system and compromising your water quality. The Importance of […]

7 Things to Know About Boiler Feed Pumps

Boiler feed pumps are the most efficient way to feed specific quantities of water into a steam generator. Boiler systems are used in many different industries. Incorporating a boiler feed pump (BFP) will provide more consistent and accurate feedwater results. If you are interested in learning more about the basics of boiler feed pumps, here […]

Why a Gear Pump is Best for Viscous Materials

Oil and other high-viscosity liquids can present a unique challenge for many pumps. Operators who regularly deal with viscous materials prefer gear pump systems because they handle difficult fluids more efficiently and effectively. Gear pumps are often found in applications like oil and gas, industrial, mining and aggregate, water and wastewater treatment, municipal, and food […]

The Benefits of an Air-Operated Double-Diaphragm Pump (AODD)

The Air-Operated Double-Diaphragm Pump (AODD) is a type of positive displacement pump that many operators prefer over standard centrifugal pumps for certain thick and viscous fluid applications. AODDs are commonly used in industries like food processing, electronics, pharmaceuticals, paints and oil, acid transfer metering, and gas. Four key benefits of Air-Operated Double-Diaphragm pumps: Simple […]

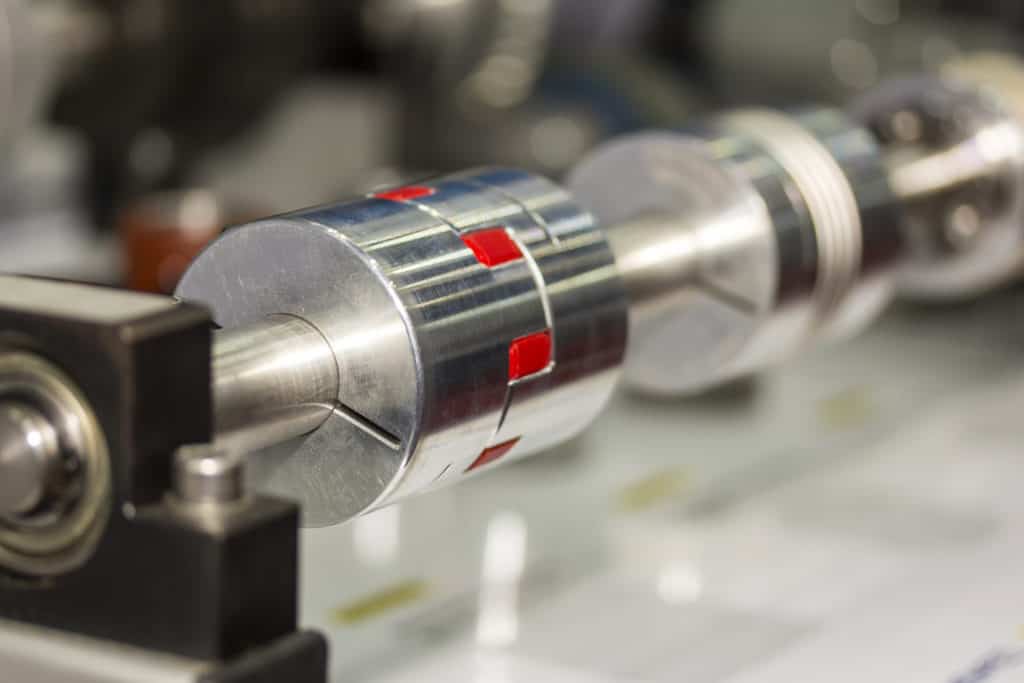

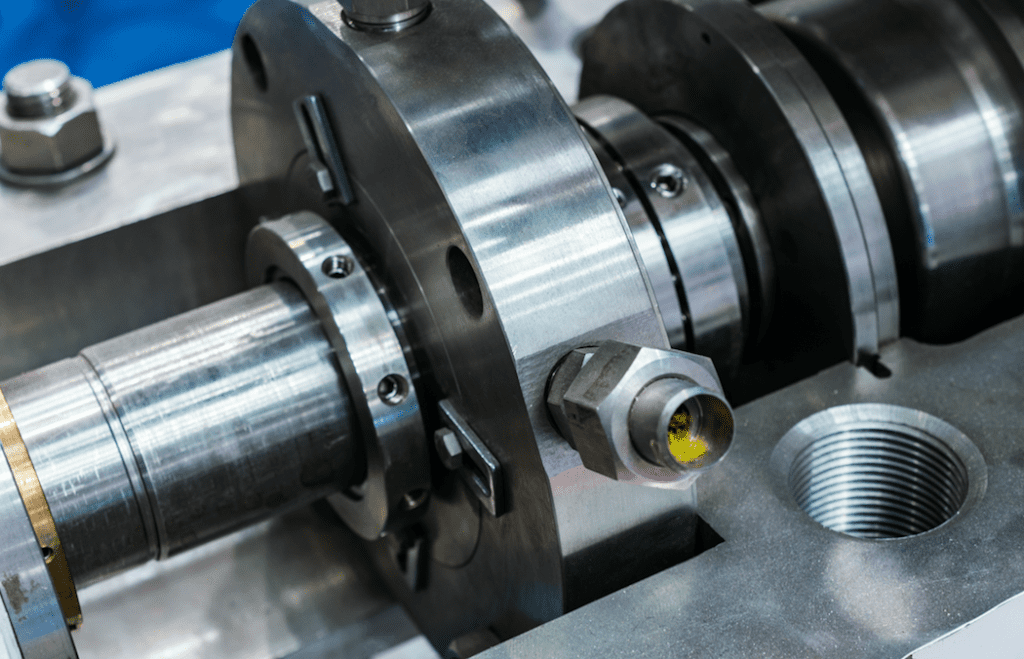

4 Drivers of Pump Bearing Longevity

Proactive maintenance is so important when it comes to minimizing downtime and extending the lifespan of your pump equipment. One of the most common sources of pump problems is the pump bearing. If the bearing assembly is damaged, deteriorated or not operating properly, it will lead to excessive heat and vibration. This leads to equipment […]

Why Use a Self-Priming Pump?

Self-priming pumps offer certain advantages over standard centrifugal pumps that require manual priming. The biggest difference is obviously that they prime themselves without the need for outside attention. Not only does this make self-priming pumps more efficient than alternative designs, it also provides additional benefits that are useful in many industrial applications. How Self-Priming […]

Pitbull Pumps Show the Advantages of Simple Design

You don’t have to have an overcomplicated design to have a quality pump. The core physics of pumping have not changed. Yet, many pump designs have evolved to have so many complex features, especially when it comes to handling solids and debris in wastewater and slurry applications. Some of these features are nice, but are […]

Verderflex Peristaltic Pumps Offer Robust Solutions

Verderflex is a leading manufacturer of peristaltic pumps, which are a specialized type of pump used in a wide variety of industries. Peristaltic pumps work using alternating compression and relaxation of a hose or tube. The hose draws contents in, then a rotating shoe rolls along the length of the hose. This provides compression […]

Preparing Pumps for Cold Weather Conditions

Winter is already in full swing and you probably already notice that operating your pumps is more challenging when the weather is colder. The colder it gets, the more difficult it is to run and maintain pumps efficiently, especially if you are pumping remote locations. Slurry pumps are known to struggle the most during […]